Quick basic engineering design of your step-up substation

PV substation engineering and design in a few clicks

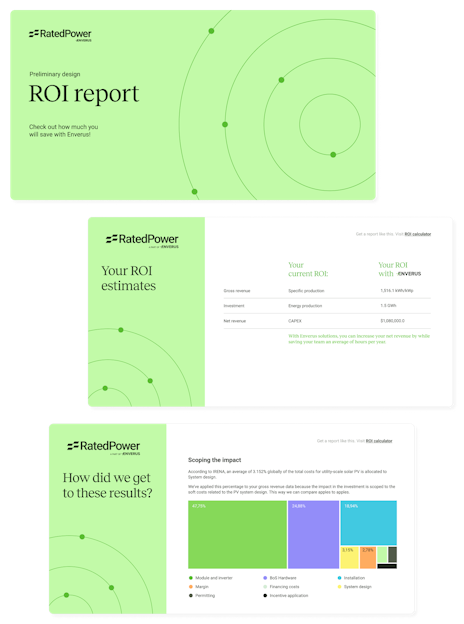

Calculate your ROI from solar, storage and hybrid software

We partnered with Enverus to help utility-scale developers, IPPs, and EPCs uncover just how much ROI they could unlock by implementing solar, storage, and hybrid design software—before their next project even breaks ground.

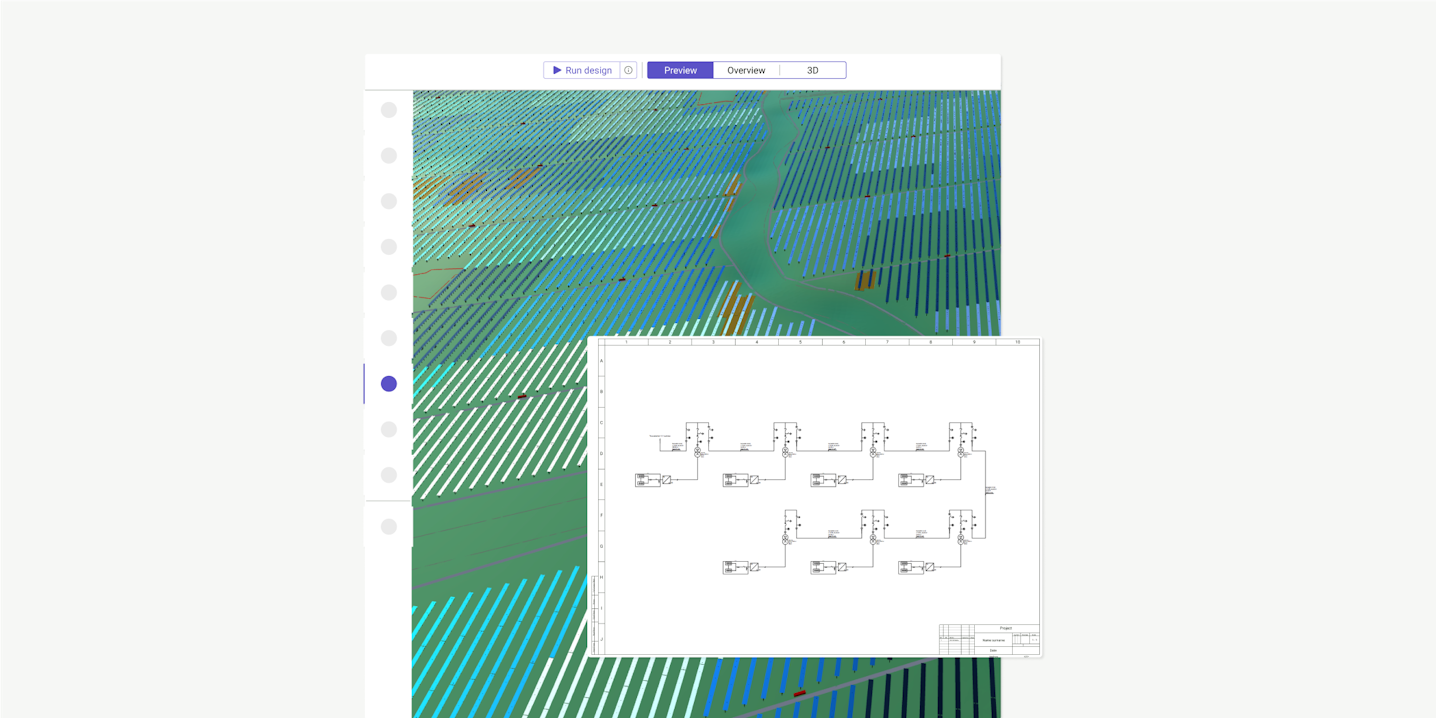

Automate the basic engineering of your substation and reduce development time

Increase the efficiency, power output, and ROI of your plant’s substation in just a few clicks

Generate the best interconnection solution

Customize your substation design

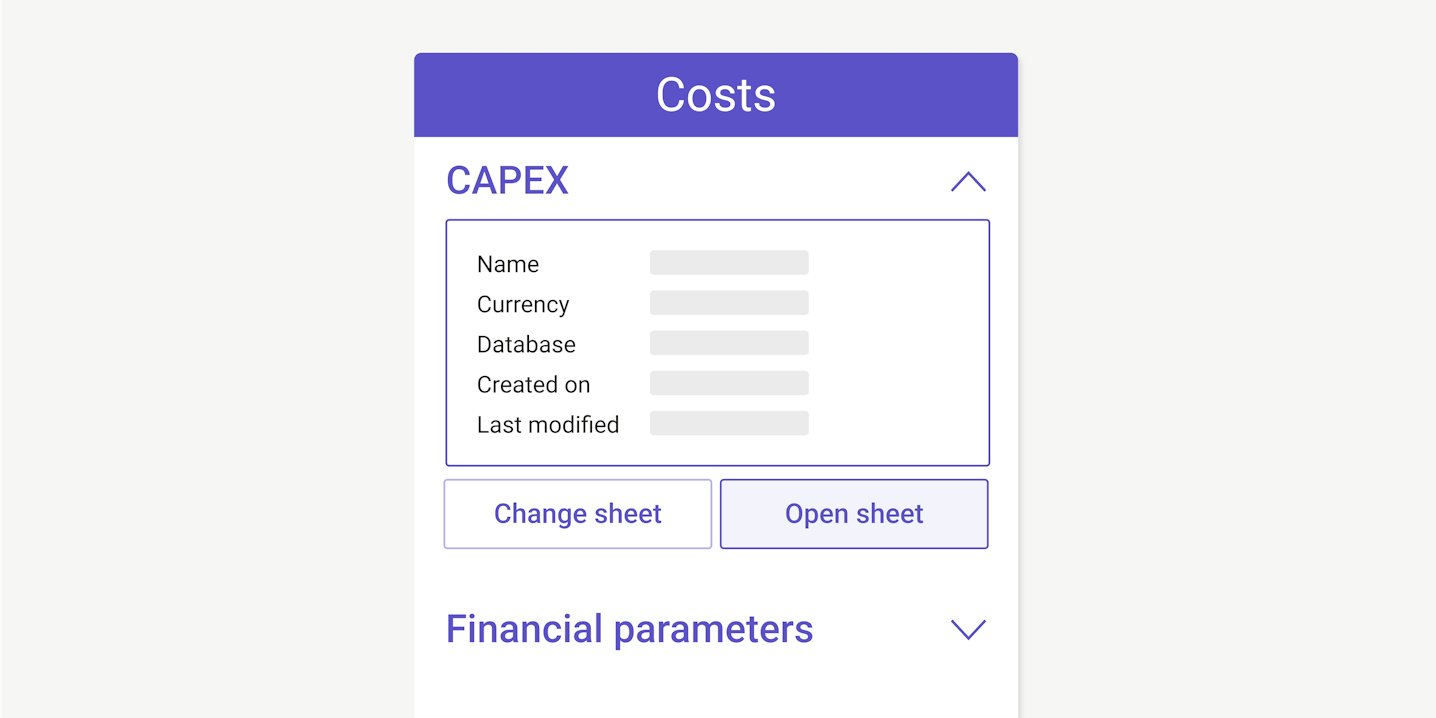

Access cost-effective calculations

Substation design software that grows with you

Basic

Get the basic engineering and feasibility studies for your utility-scale plants all the way to the grid point.

Includes unlimited users, projects and designs.

Advanced

Perform solar PV detailed engineering and get your project ready for off-taker.

Includes unlimited users, projects and designs. Also, everything in Basic plus:

Enterprise

Identify buildable sites, reduce project siting risks, and get the full cycle engineering —from site analysis to detailed engineering.

Includes unlimited users, projects and designs. Also, everything in Advanced plus:

Take a free product tour

Thousands of professionals choose to work with our PV engineering and design software

EPCists expediting PV design and deliverables with solar software

«We looked for a tool that was quick for performing basic design and optimization, automatically producing deliverables. RatedPower increased the number of bids we could prepare and submit by around 50%.»

RatedPower's speed helps us boost our competitive advantage

«Now we can turn around design documents within hours and minutes to stakeholders, landowners, partners or engineers, to get through our regulatory process. This has allowed us to move projects forward faster.»

Accelerating solar design from 5GW to 30GW per year

«Before RatedPower, there was a high level of variability, simple land layout to more irregular layouts. Now, we can quickly filter down sites from what is possible to what is realistic.»

Harnessing RatedPower to carry out invaluable PV equipment analysis

«RatedPower provides us with simplicity and flexibility in our solar projects while requiring fewer resources. Other software options typically demand more resources on our end to complete these calculations.»

Empowering solar PV design customization through faster iterations

«In one or two weeks, I became very familiar with the software. I was able to do more iterations on our solar layouts, and we could fill the interconnection requests in no time.»

Competitive positioning in large-scale overseas PV plant bidding

«RatedPower has a solid customer base and good reputation abroad. It delivers required documents in multiple languages for our global bids while adopting international design standards»

Optimizing PV projects and overcoming the limitations of legacy software

«We have received a highly professional response when we needed support or training from the team. RatedPower helps us optimize our projects and provides us with a significant advantage over our competitors.»

Doubling PV project development bandwidth with RatedPower

«Thanks to the new developments created by RatedPower that adapt to our needs, we could double our capacity. The time we used to spend on designing and reviewing designs is now focused on doing more projects.»

Enhancing land assessment efficiency for PV developers

«RatedPower produces a set of documentation to deal with most of the environmental agencies' requirements and for application of grid connection authorization processes.»

Centralizing solar development in one app

«We used to use a mix of tools like AutoCAD, spreadsheets and PVsyst. Now with RatedPower, our team can be innovative and explore more possibilities without wasting time, as each design only takes minutes to run.»

Aligning stakeholders from development to procurement

«The solar industry is becoming more volatile and complex. In today’s world, developers, contractors, and buyers need flexible, scalable and configurable cost estimation tools linked to design for running different scenarios.»

A three-in-one software that saves PNE time and resources

«It's easy to use, even for non-technical users. Now, anyone in our offices can efficiently create their own designs, and our German engineers can manipulate anything in our projects remotely since RatedPower's platform is cloud-based.»

Driving efficiency and optimizing resources for more than 50 projects

«RatedPower offers highly personalized customer support. The team has been efficient in solving our doubts and helping us learn how to make the most out of the tool based on our unique needs.»

Get real-life inspiration from energy professionals like you

Check how other development and engineering teams are leveraging software to increase ROI and mitigate risks of their utility-scale solar assets.

Learn more

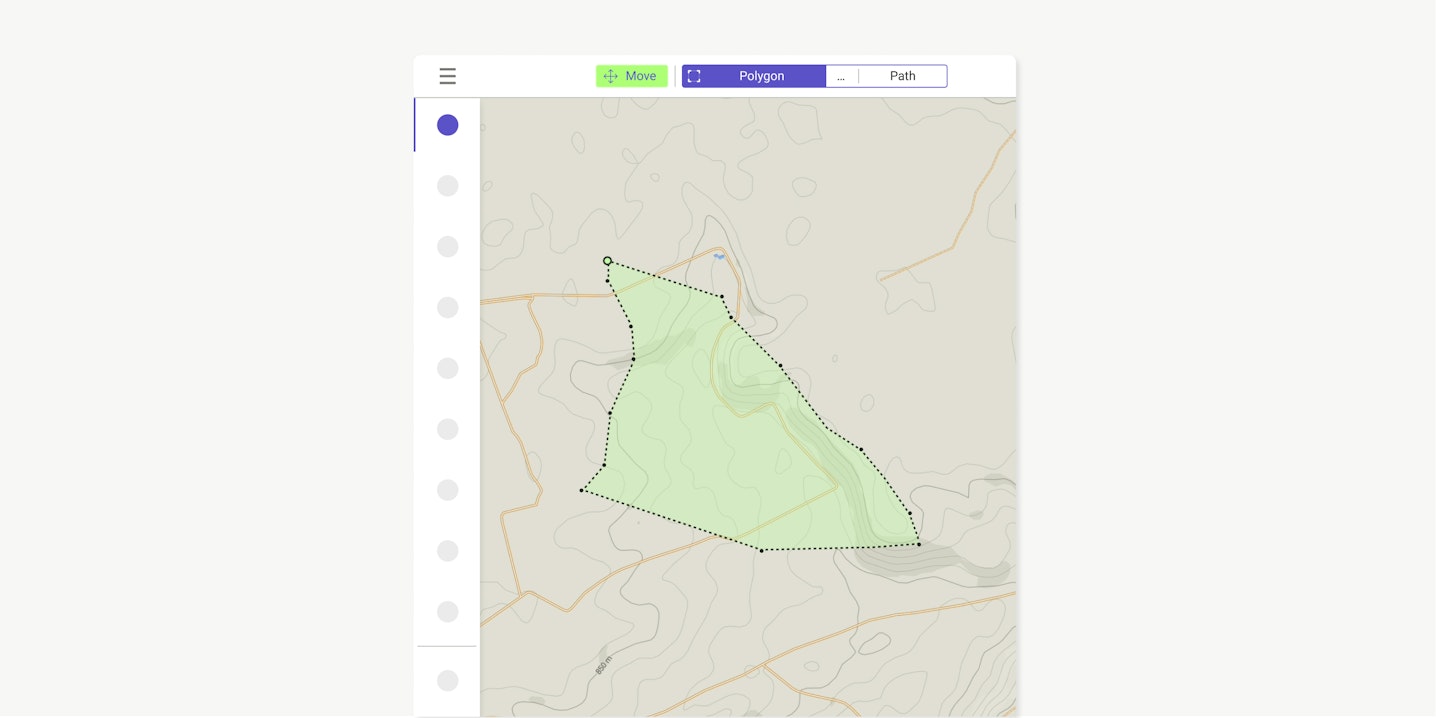

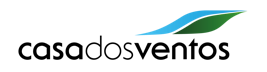

PV site analysis tool

Selecting the right plot of land and mitigating project risks involves considering numerous factors such as interconnection capacity, pricing trends, competition, land suitability, and future economic viability.

Solar planning tool

Equip your development team with smart site assessment, project design, and optimization in a collaborative PV planner.

Solar modeling tool

Reduce risk to your PV project with easy-to-use advanced solar modeling software, increase ROI, and grow your business pipeline.

Battery energy storage system design

The future of utility-scale PV projects is hybrid. Design your BESS and optimize its capacity in one tool. Download basic engineering documents and format its layout in an instant.

Solar proposal software

Slash feasibility assessment times, reduce site analysis costs and boost your PV asset profitability.

Solar irradiance calculator

Accurate solar irradiance data is the foundation of your future PV plant. You can easily upload your own TMY dataset in .csv or connect to trusted sources to ensure the bankability of your utility-scale solar project.

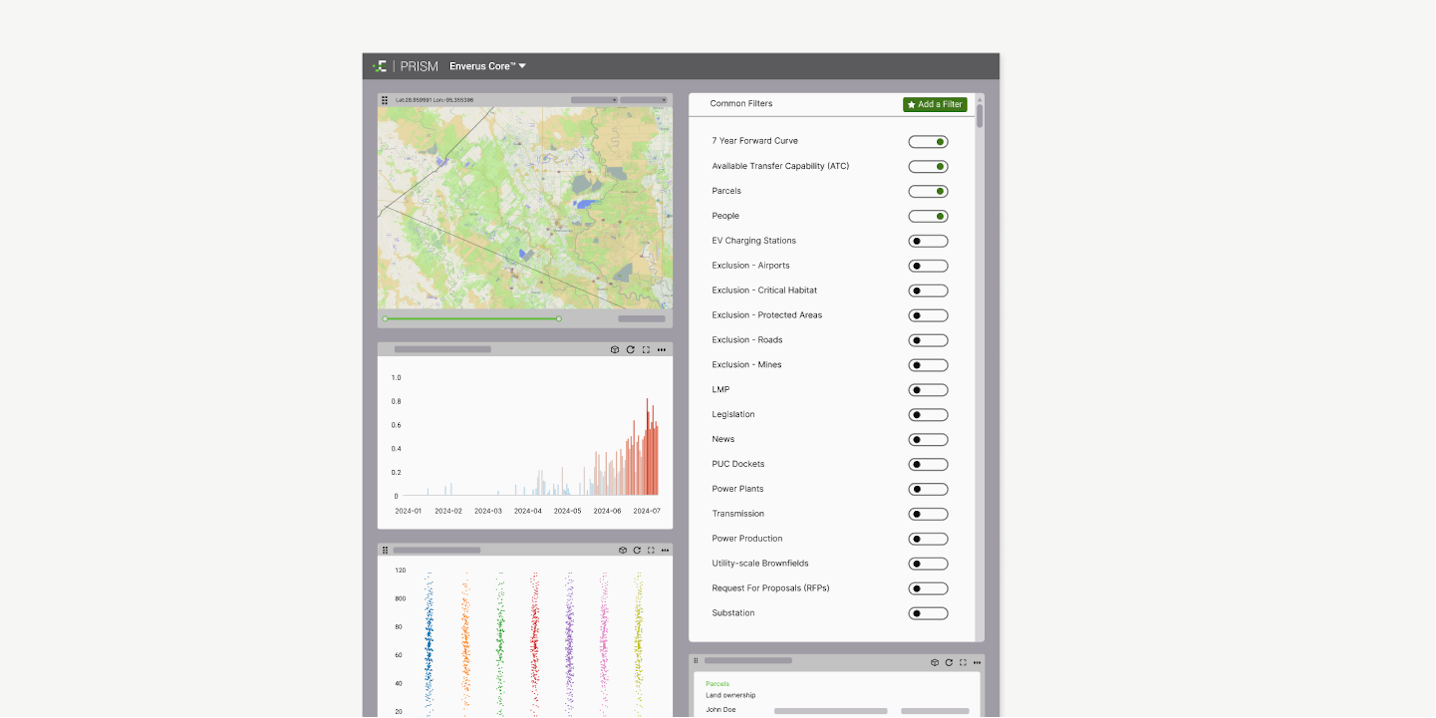

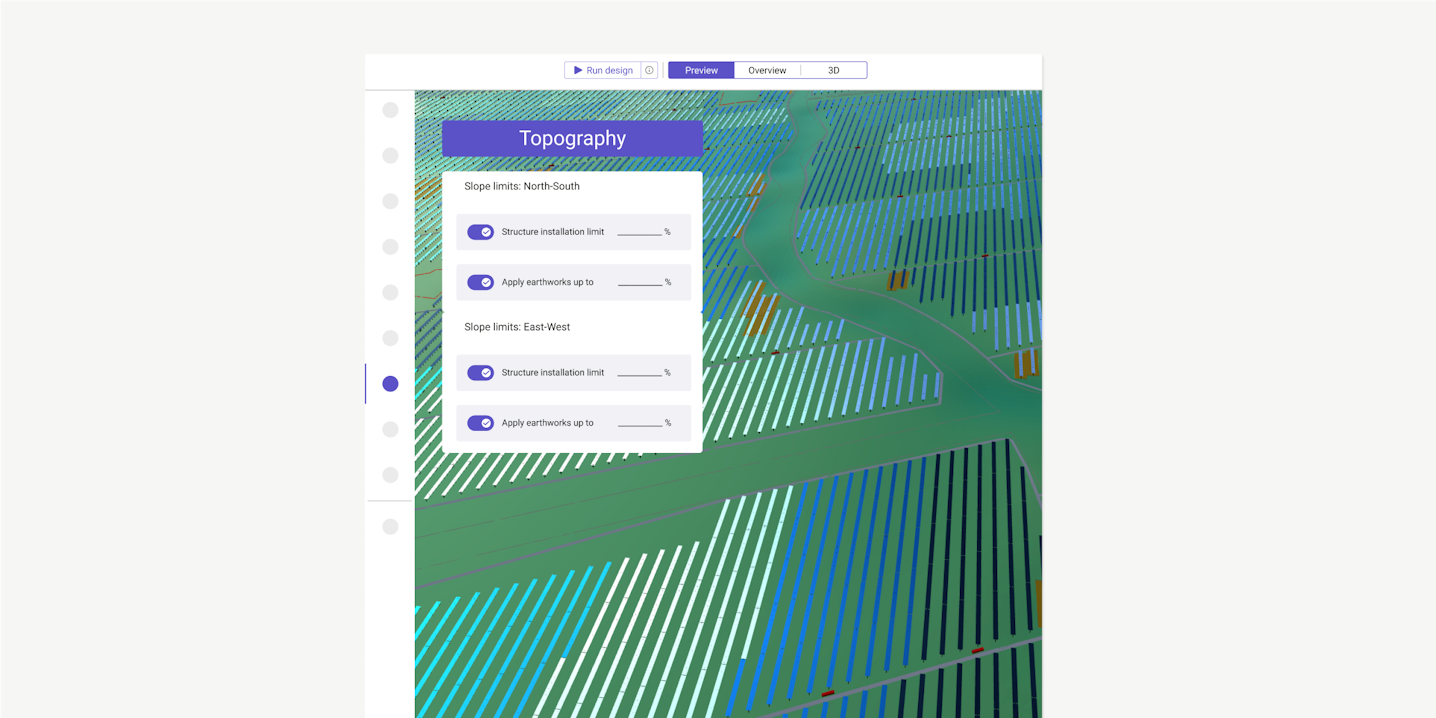

Earthwork estimating software

Use the earthwork estimating module to collect more accurate topography estimations for your projects and minimize your financial risk.

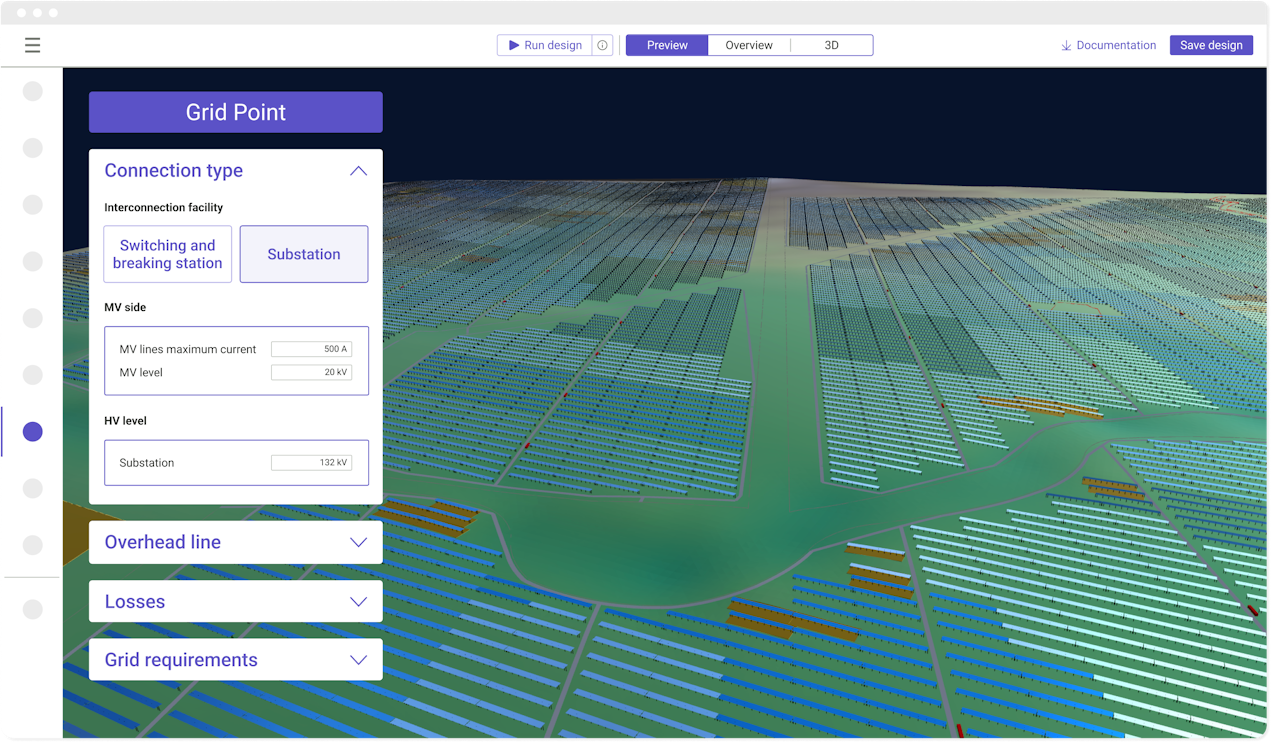

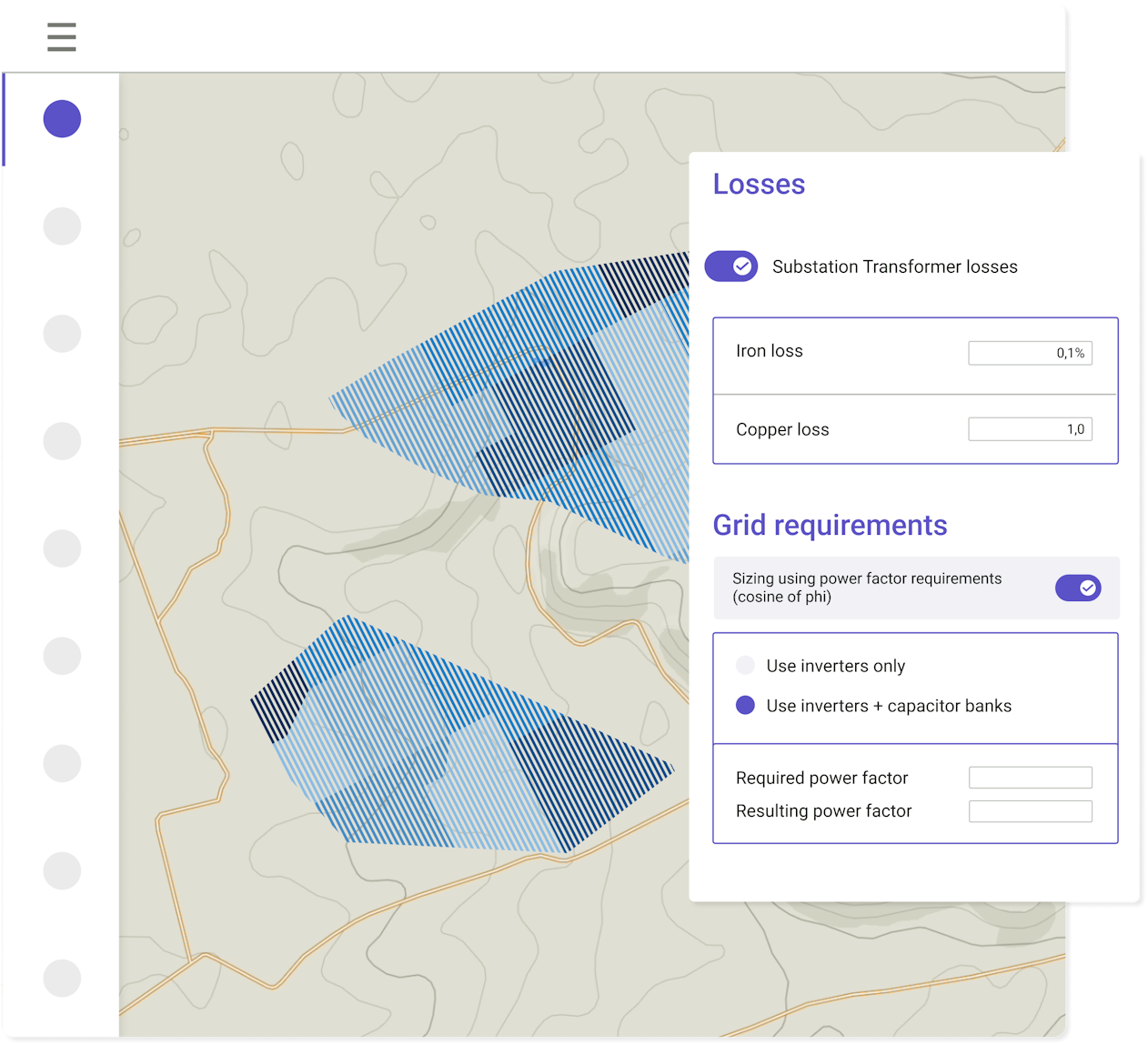

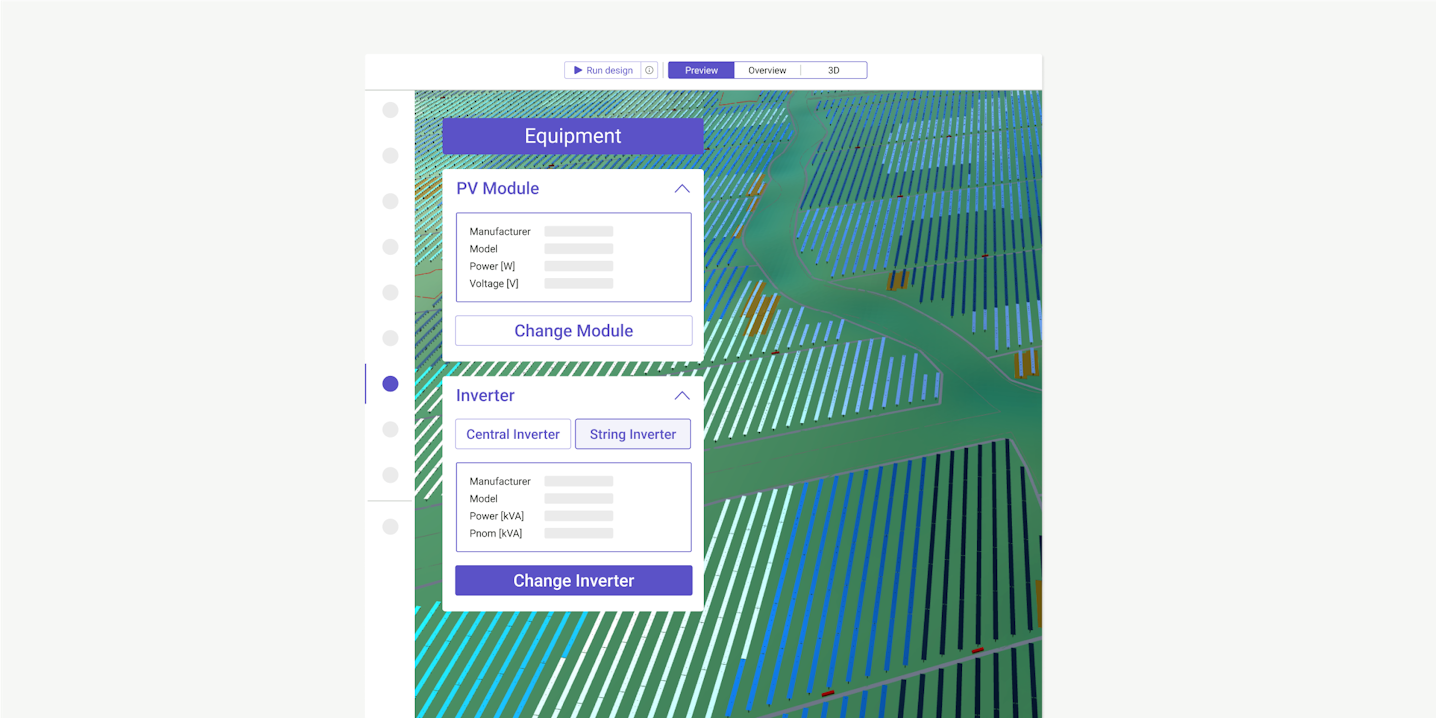

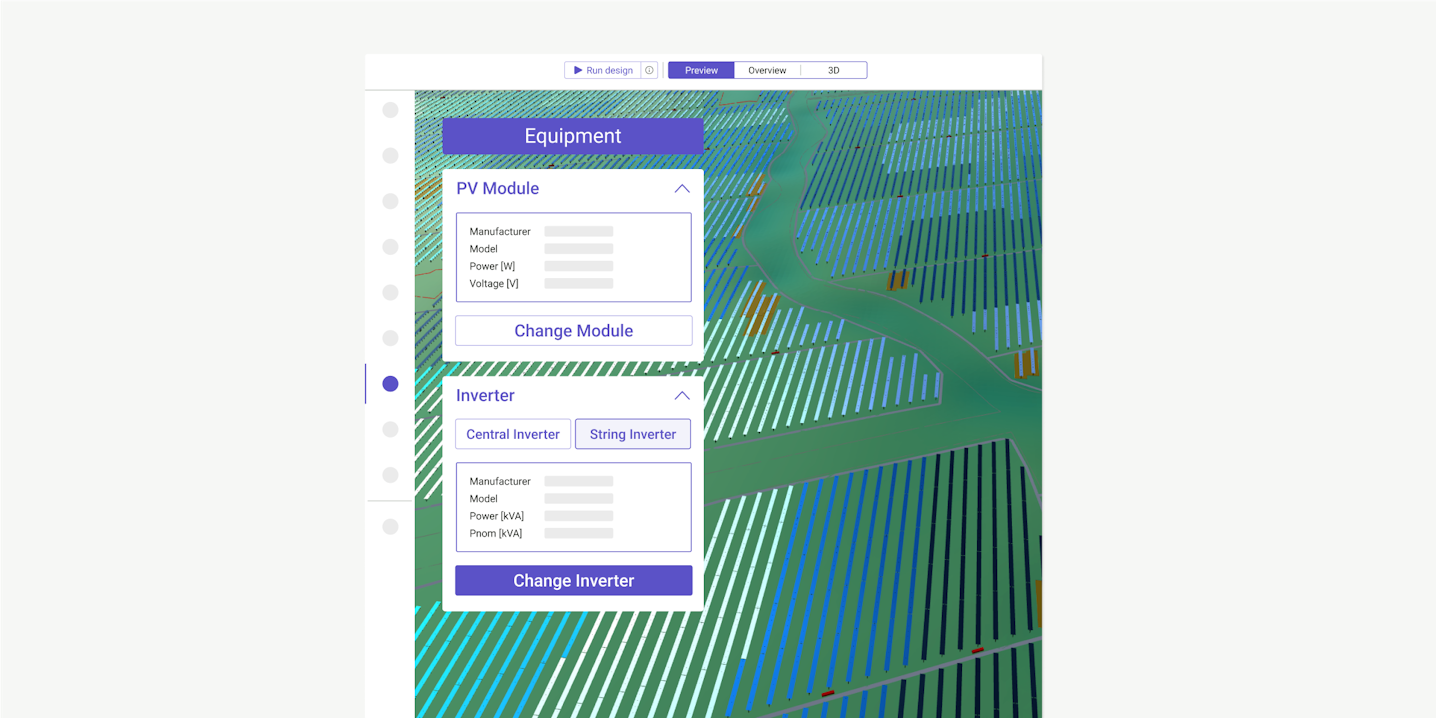

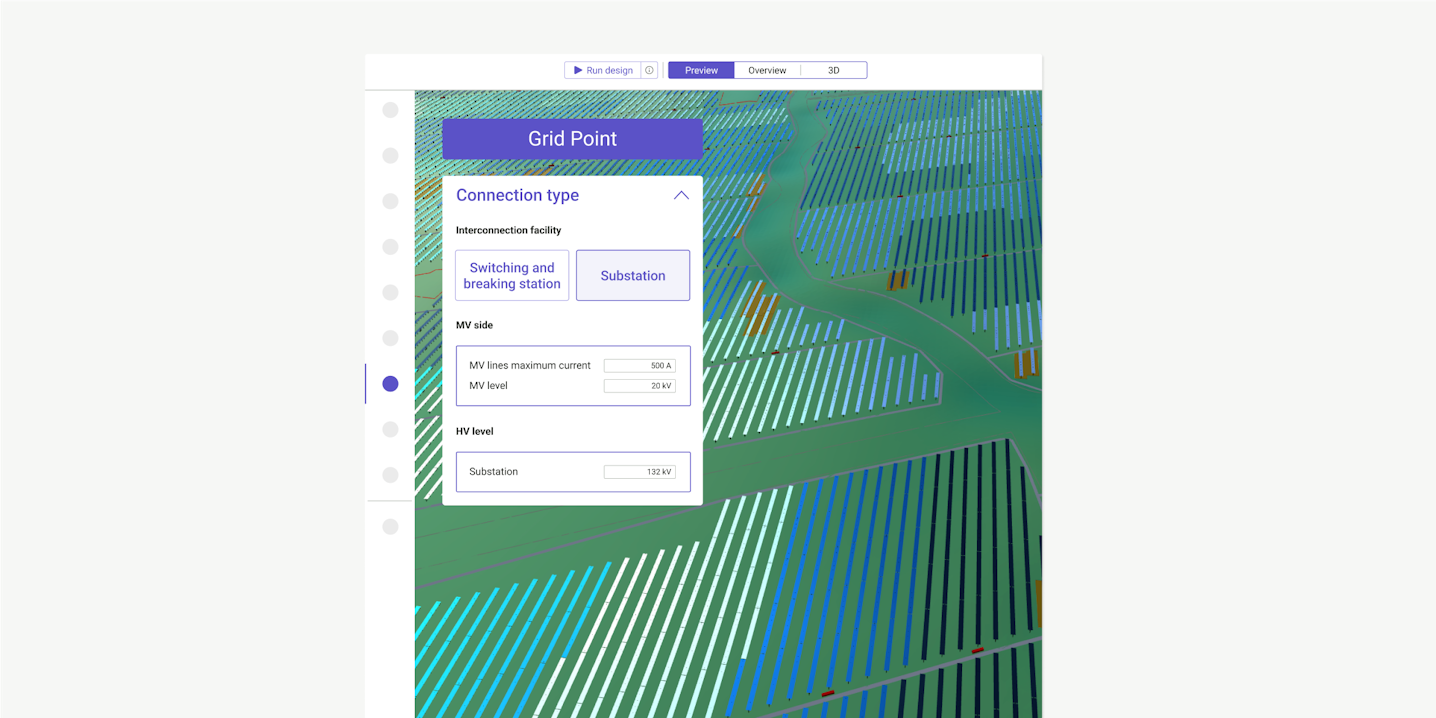

Substation engineering

Easily choose elements such as your facility interconnection type, overhead line type and grid requirements to achieve the highest rated power for your plant while also considering your grid operator, the utility, and the country where it is located

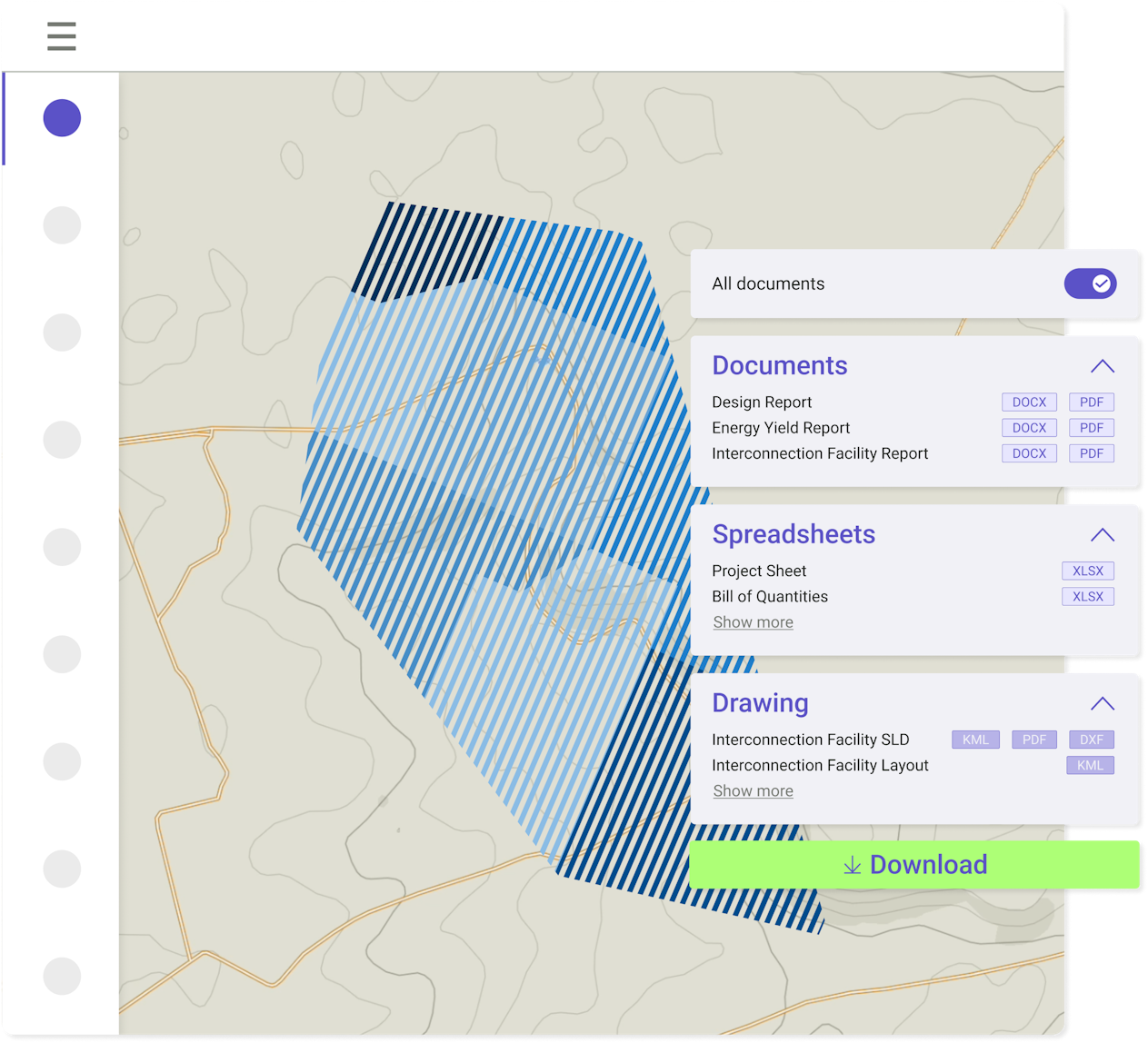

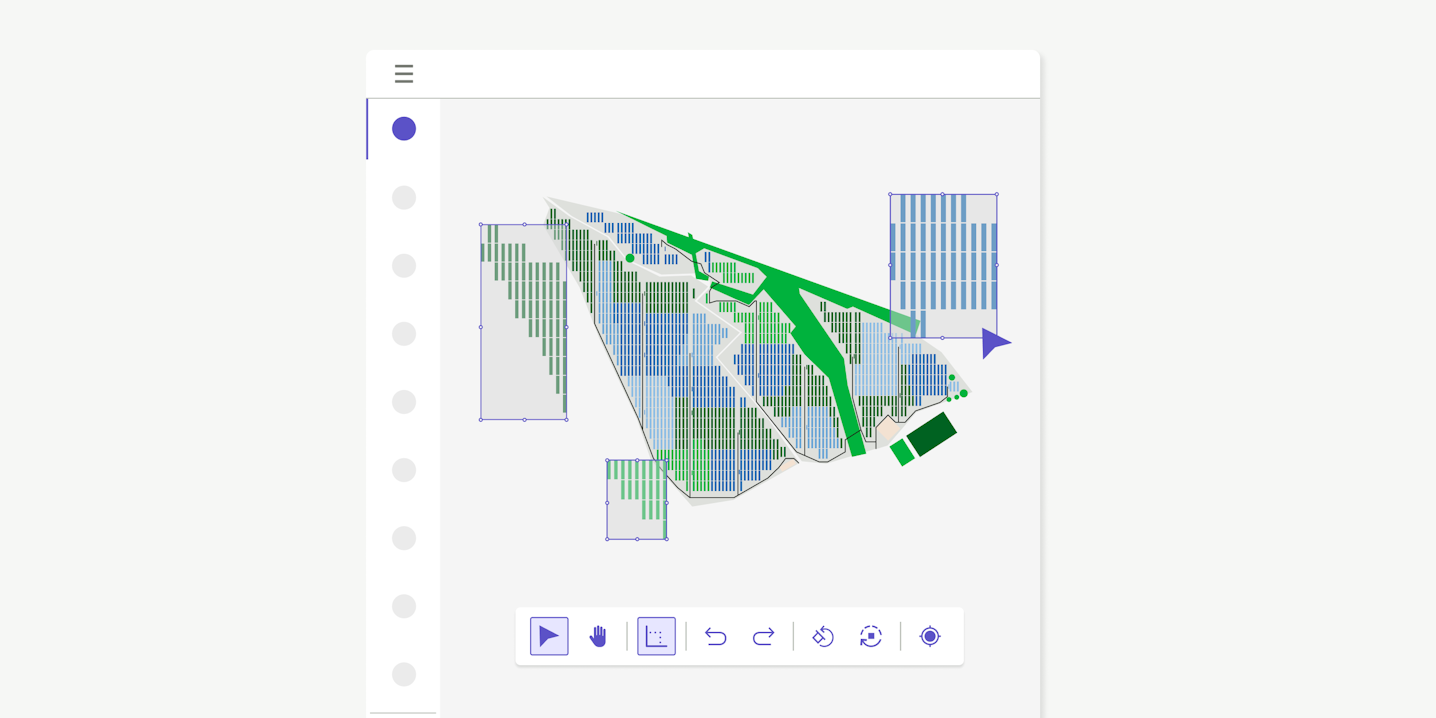

Detailed engineering ready for off-takers

Manually fine tune your automated design with real-time data on energy production, costs and more. Get the project detailed engineering ready for the off-taker.

- RatedPower

- Platform

- Substation