- Solar energy blog

- Comparing AC vs DC-coupled BESS in utility-scale solar projects

Comparing AC vs DC-coupled BESS in utility-scale solar projects

Read on to discover the comparative benefits of AC vs. DC-coupled BESS for utility-scale solar projects.

Natalia Opie

Manager of Customer Success

Natalia Opie leads the Customer Success team for RatedPower. She is passionate for renewable energies and their role within the global environmental transition and has a thorough understanding of the solar industry, backed by her BSc in Energy Engineering, her MSc in Renewable Energy in Electrical Systems, and six years of experience partnering with clients of different countries to develop profitable, optimized assets.

When designing a solar installation with an integrated battery energy storage system (BESS), one of the key considerations is whether to use an AC or DC-coupled system.

In this blog, we’ll go into the subject and explore which type of system is better for utility-scale solar PV projects. Make sure you watch the full webinar we carried out on the topic for even more information here.

AC vs. DC-coupled systems

We defined and covered the difference between the two types of systems in more depth in one of our recent blogs; however, to summarize:

AC-coupled systems require the use of multiple inverters to convert the power generated to the proper format. They are more flexible and easier to install into existing systems than DC-coupled but tend to be more expensive and less efficient.

DC-coupled systems use the same inverter as the solar field to convert the DC power stored in the BESS into usable AC output to the grid. They are cheaper and more efficient than AC systems but less flexible and resilient as they rely on a single inverter.

Choosing AC vs. DC in utility-scale projects

Utility-scale solar PV projects typically refer to installations that generate more than 10 MW of power, but definitions can vary. These large-scale projects usually involve multiple stakeholders, investors, and contractors and span relatively large geographic areas.

They can be designed to include BESS either on-site, off-site, or with no storage capabilities.They are often connected directly to the grid and supply power for downstream consumers through the grid.

With the cost and complexity of these projects, it is important to pick the right type of coupling for your BESS. Using our solar design tool, you can model your project and experiment with whether AC or DC coupling would suit your specific needs better.

Modeling BESS in RatedPower

RatedPower allows you to model every aspect of your next project, from leveraging accurate location data and modeling shading losses to specifying AC/DC ratio and Pmax. It also allows you to pick between modeling with an AC-coupled BESS system or a DC-coupled one, as well as defining the size and specifications of your chosen BESS, letting you see how your installation will perform under each condition.

In our recent webinar, we modeled an example utility-scale project using AC and DC-coupled BESS to illustrate the benefits of each during the design process. Let’s look at the results of each model.

DC-coupled BESS

When using DC-coupled BESS, your BESS will be located within the power plant itself. It is, therefore, important to consider how much space you have on your site, the layout of your modules, and the angles at which they are positioned. Having said this, DC-coupled systems tend to take up less space overall and are, therefore, better for projects with a more limited area to work with.

You can download a bill of quantities using RatedPower, which breaks down all the components you need for your system. With DC-coupled systems, this list is relatively short due to the fewer pieces of equipment required and the fact that the BESS is located on-site. As a result, DC-coupled systems tend to be the cheaper option and more appealing for projects with smaller budgets.

You are also able to download the energy results using RatedPower. In the Battery Energy tab, you can find the energy clipping loss data tracking the amount and type of overpower loss experienced by the plant that can then be used to charge your BESS. To note here, you can decide at what time intervals you would like to measure the data, be that monthly, hourly, or sub-hourly.

The losses that can be leveraged by DC-coupled systems are the inverter overpower losses. In other words, the amount of power produced by the solar field that the inverter cannot convert, also known as clipping at the inverter level.

A curtailment applied at the Point of Interconnection (POI) might produce excess energy that cannot be utilized when using DC-coupled BESS, meaning that if you are oversizing your plant using a high DC/AC ratio, DC-coupled is the best way to go, as you can take advantage of losses in the system to charge your BESS.

AC-coupled BESS

When designing a plant with AC-coupled BESS, your BESS will often be located outside the main array area. This helps save space within the array itself. However, it is crucial to keep in mind how much space you have on your site as a whole and ensure you leave enough room for any BESS.

The bill of quantities for AC systems is far longer than that seen with DC. This is a result of the additional equipment and components AC-coupled systems require, such as multiple inverters. Additionally, considering AC systems are often placed outside the main site, there are more construction and engineering costs to contend with when installing the BESS.

This, in turn, translates into AC systems being more expensive than DC ones and thus better suited to larger projects and those with bigger budgets.

With AC-coupled systems, the interesting loss would be the clipping originated by setting an active power curtailment. Here, the grid can no longer take more power, or we simply prefer not to inject all the produced power into the grid. It might be more financially advantageous to store and sell it when the price is higher (arbitration). If your POI has a specific cap in place, AC-coupled BESS is usually the optimal choice to take advantage of your clipping losses.

Which is best?

To conclude, both AC and DC-coupled BESS have their advantages and disadvantages. When it comes to utility-scale projects, the better choice will depend on the grid’s characteristics, the region’s legislation, and site availability.

The higher costs and space requirements of an AC-coupled system are less of a consideration for utility-scale projects as they are far larger by definition than other types of projects and tend to have greater investment and higher budgets.

Whether you go with an AC-coupled or DC-coupled system, the electrical system can be sized to favor the relevant type of clipping losses so that the BESS can be charged efficiently.

AC-coupled systems are typically more popular in the utility-scale industry given their rapid response time to provide ancillary services, plus their modular nature. AC-coupled systems can act as an “add-on” to pre-existing PV plants or be permitted in parallel to the PV plant. If we remove an AC-coupled system from a hybrid PV+BESS facility, the PV plant design is still valid except for the interconnection piece. If we remove a DC-coupled system instead, the electrical design and the sizing of the PV plant will have to be reassessed.

If you’d like a more detailed breakdown of everything discussed here, plus a great question and answer session, be sure to check out the full webinar here!

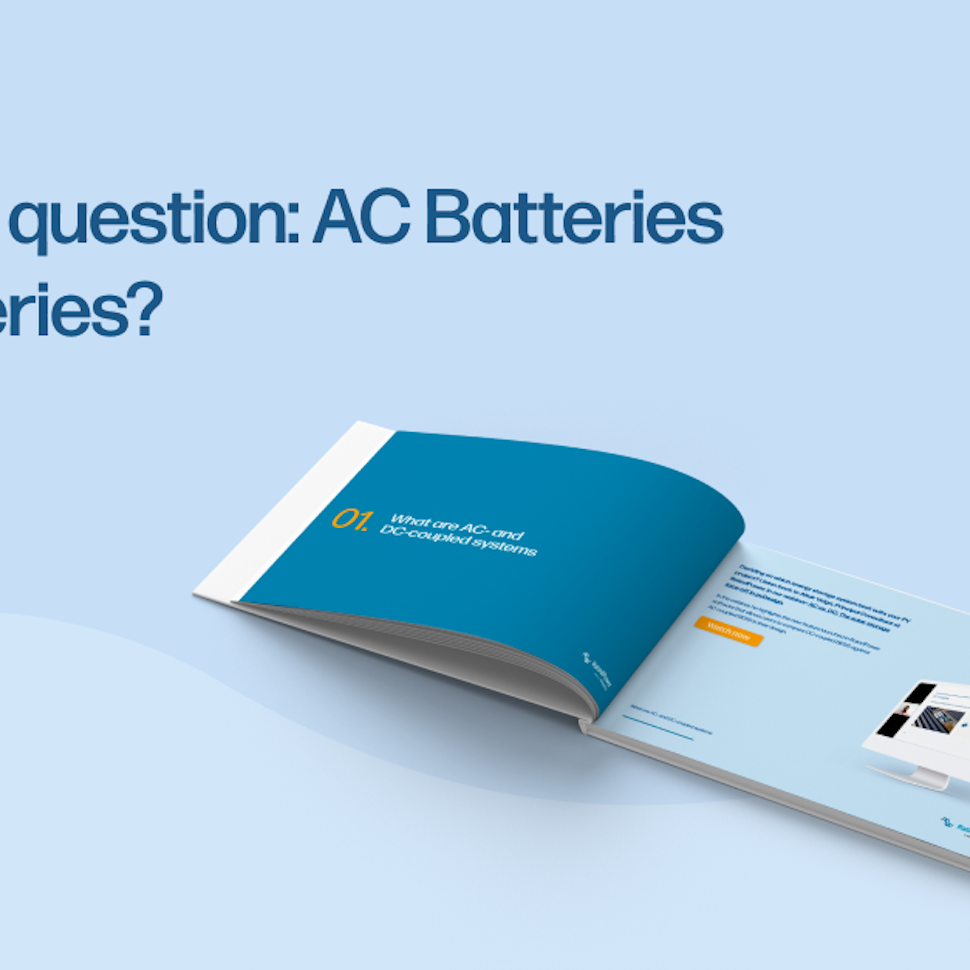

The eternal question: AC or DC Batteries?

In this eBook, we’ll look at these two options in-depth and explore which type of BESS is best for which situation when it comes to designing a solar installation

Latest stories

Related posts

Technology and engineering

Innovation in renewable energy: Developments expected in 2025

We look at the 10 biggest renewable industry developments that are making a green future possible, including perovskite solar cells, green hydrogen, and more.

Updated 18 MAR, 25

Technology and engineering

What the future holds for the longevity and efficiency of solar panels

Tests done by the French photovoltaics group Hespul showed that the panels, installed in 1992, are still operating at an astonishing 79.5% efficiency. Read on to find out more.

Updated 4 MAR, 25

Technology and engineering

Concentrated solar: An unlikely comeback?

Once described as obsolete, the concentrated solar power market ballooned to $53 billion in 2023 and is still growing. Here’s why CSP is making a comeback.

Updated 12 NOV, 24

- RatedPower

- Solar energy blog

- Comparing AC vs DC-coupled BESS in utility-scale solar projects