- Solar energy blog

- The power of battery storage: Evolution and alternatives

The power of battery storage: Evolution and alternatives

Laura Rodríguez

Business developer

Laura is a renewable and software industry sales professional, currently working at RatedPower as Sales Overlay in North America & Territory Manager Oceania. With a background in International Business and International Trade, Laura previously worked in the business strategy area in various companies as well as as a market analyst for the Government of Spain in Australia.

Content

- The changing nature of battery storage

- Redox flow batteries

- Solid-state batteries

- Lithium-air batteries

- Lithium-ion batteries

- Can batteries replace fossil fuels in the energy system?

- Emerging alternatives to batteries

- Hydrogen fuel cells

- Graphene supercapacitors

- Applications of BESS in a PV plant

- Grid ancillary services

- Energy arbitrage and load management

- Transmission resource management

- Microgrids

Developing battery storage solutions is key to enabling the transition to clean energy, providing a way for renewable sources of generation to provide base-load electricity supply.

Large quantities of intermittent supply will need to be integrated into power grids around the world. In fact, around 10,000 gigawatt-hours of energy storage capacity, including batteries, will be needed by 2040 to meet climate goals –– which is 50 times the size of the current market, according to the International Energy Agency (IEA).

Utility-scale storage systems, typically based on lithium-ion batteries, have so far primarily been deployed in Australia, Germany, Japan, the UK, and the US. The Americas are set to overtake Asia-Pacific as the largest battery storage market by 2025, with global storage capacity rising by 70GWh to 729GWh by 2030.

Despite the COVID-19 pandemic, global investment in battery storage increased by almost 40% last year to $5.5 billion, according to the IEA. Strong momentum in the sector and a large project pipeline are set to continue the trend in 2021.

Let’s look at some of the different forms of battery storage available today and the role they’re playing in the energy transition.

The changing nature of battery storage

Battery storage systems are used to provide balancing services for electricity grid operators, and are increasingly being installed alongside solar and wind farms to store power for use overnight when the sun isn’t shining or when wind levels are low. Batteries can make power grids more resilient and provide backup to reduce blackouts in countries where grids can become overloaded by demand outpacing insufficient supply.

Battery installations have so far been predominantly based on lithium-ion batteries. But other battery technologies are emerging that could form part of the energy infrastructure of the future.

Redox flow batteries

Redox flow batteries, typically using the metal vanadium, have a relatively low energy density so they are not a replacement for lithium-ion batteries in electric vehicles. However, they have advantages in stationary energy storage applications as space and weight are less of a concern and installations can be scaled up to meet the required capacity.

Vanadium redox flow battery (VRFB) technology is based on liquid vanadium electrolyte that unlike lithium-ion, does not degrade over time and is dissolved in a non-flammable, water-based solution to generate electricity.

While lithium-ion batteries can replace peaking power plants that are called on to meet spikes in electricity demand, redox flow batteries can shift renewable output from the middle of the day to when it is most needed every day. And they can do this while maintaining their recharging capabilities throughout the 20–30-year life of the solar or wind installation.

VRFB installations in places like China, Japan, and Australia have been small so far, but there are plans for large installations of around 100MW. UK-based VRFB developer Invinity Energy Systems has signed a deal with Germany’s Siemens Gamesa Renewable Energy to develop grid-scale batteries. Bushveld Minerals, a vanadium mining company that has previously invested in Invinity, is also part of a consortium that owns VRFB producer Enerox and has its own Bushveld Energy subsidiary.

Solid-state batteries

In the same way that solid-state hard drives offer more efficient and stable data storage than previous technologies, solid-state lithium batteries use solid electrolytes that offer higher energy density and do not carry the same safety risk as lithium-ion batteries. They require fewer safety components, so save valuable space, allowing for larger capacity in a single installation. They also have a longer lifespan and are not affected by external factors such as temperatures like lithium-ion batteries.

South Korea’s Samsung SDI has been exhibiting solid-state battery technologies since 2013. Mass adoption is some way off, however, as the cost of producing solid-state batteries is high. And the solid electrolyte requires lithium metal, whereas most of the lithium mined globally is in the form of lithium salts that are used in liquid electrolytes.

Lithium-air batteries

Lithium-air batteries create a reaction that uses oxidation of lithium in the anode taking oxygen from the air, and the reduction of oxygen molecules in a carbon cathode, to generate energy. This provides a much higher energy density than lithium-ion and the use of oxygen makes for the lightest possible batteries.

However, there is still work to be done on reducing the safety risk of using a highly reactive pure lithium anode, and increasing the technology’s low charging efficiency. UK-based chemicals producer Johnson Matthey has been working with the University of Liverpool to research minimizing the reactivity that degrades the performance of the electrolyte during battery cycling, increasing the performance and stability.

Lithium-ion batteries

The energy density of lithium batteries has increased in recent years, as manufacturers have experimented with different combinations of materials in the cathode and anode. Costs have fallen sharply over the past decade, making batteries viable for more projects. Although grid costs are flat or even rising, the cost of a four-hour duration lithium-ion battery system is forecast to decline by 68% to $104 per kilowatt hour (kWh) by 2050, down from $320/kWh in 2020, according to Bloomberg.

The use of lithium-iron-phosphate (LFP) cathodes gave way to lithium nickel-cobalt-manganese (NCM) in various quantities, which offers a larger storage capacity but raises safety issues. There are also concerns about the sourcing of cobalt metal, which is subject to large price swings. In some cases, manufacturers have chosen to opt for LFP batteries to allay safety concerns and encourage adoption.

Lithium-ion battery anodes are typically based on graphite. As manufacturers look for ways to increase the time between battery charges, some are turning to silicon metal as an alternative. Companies like Norwegian silicon producer Elkem and US battery materials startup Group14 Technologies are starting to supply manufacturers with battery-grade silicon for anodes to substitute graphite.

Lithium-ion batteries generate energy by passing lithium ions from the anode (negative electrode) to the cathode (positive electrode) through electrolyte, sending electrons through the wire.

The combination of lightweight, high energy density and rechargeability have made lithium-ion batteries the standard since the 1990s for consumer electronics devices and home appliances. They also have applications in commercial devices and industrial goods to provide backup power, such as in the telecom industry for data centers and base stations.

Advances in technology and declining prices have seen lithium-ion batteries play an integral role not just in energy storage alongside renewable generation, but also grid balancing services and electric vehicles.

In fact, electric vehicle batteries that no longer have sufficient capacity to run an engine can be repurposed for energy storage to extend their useful lifespan.

Can batteries replace fossil fuels in the energy system?

Batteries have become an integral part of the push to reduce greenhouse gas emissions. They have done this by replacing internal combustion engines in a growing number of new car models manufactured around the world and increasing the share of renewable electricity in the generation mix.

The race among automotive manufacturers to develop smaller batteries with higher energy density and lower costs that will address consumers’ concerns is also driving growth in the energy storage market.

The large-scale deployment of battery storage is key to renewable systems replacing fossil fuels in power generation by maintaining supply during periods of low sunlight or wind levels. Energy systems that incorporate batteries can increase their return on investment as they store excess electricity that would otherwise be lost and enable it to be used as needed.

Fossil fuels accounted for around 62% of global electricity generation in 2021, with renewables at 38%. To keep global warming to 1.5 degrees, wind and solar capacity must expand at compound annual growth rates of 20% each year to 2030, according to energy think tank Ember.

Batteries are already economically viable as replacements for gas or oil-fired peaking plants, which switch on for short periods when demand spikes. The world’s largest battery storage installations are reaching 300-400MW capacities — big enough to replace small fossil fuel power plants.

An increasing number of projects call for hybrid installations combining storage with solar panels and/or wind turbines. Storage works well with solar in providing base-load, continuous power as solar output is broadly predictable based on hours of daylight and seasonal patterns.

According to the Rocky Mountain Institute, a continuing decline in costs will make clean energy portfolios competitive with the operating costs of combined cycle gas plants (CCGTs) within 10 years based on a range of natural gas prices. “Modeling these solutions suggests that such CEPs will begin to compete after 2025, depending on gas prices. In reality, however, they will likely compete earlier for portions of those gas plants’ loads, since batteries at multiple scales can contribute to managing and flattening demand and generation profiles,” the report said.

Emerging alternatives to batteries

While battery technologies have clear advantages, they are based on relatively rare and expensive metals that can also have high environmental costs. Researchers are starting to look beyond batteries altogether to alternative technologies that can affordably store large amounts of energy with a lower carbon footprint.

Hydrogen fuel cells

Unlike lithium, hydrogen produces only water as a byproduct, making it cleaner to produce and recycle. It also has a much higher energy density. Many executives in the automotive and industrial sectors view hydrogen as the long-term solution to clean energy storage.

However, extracting large amounts of hydrogen from water is currently only cost-effective using fossil fuels. Research and investment are focusing on green hydrogen, which is produced using renewable energy, and governments around the world have started to release hydrogen strategies for the coming years.

Japanese carmaker Toyota has long been working on hydrogen fuel cell technology and sells the first mass-produced hydrogen-fueled car, the Mirai. In 2019, it installed a stationary fuel cell generator at one of its plants in Japan to test its commercial viability.

However, widespread adoption of hydrogen fuel has so far been limited as it is more flammable than gasoline and dangerous to transport in large quantities, posing an even larger risk of explosion or fire than lithium. Solving the safety issue will be key to making hydrogen a viable alternative.

Graphene supercapacitors

Supercapacitors hold less energy than batteries, but they can discharge and recharge energy more efficiently than batteries. Researchers have recently found that using thin sheets of graphene, which has a large surface area that can store energy, can increase the amount of energy that supercapacitors can hold. Graphene sheets would also save weight and allow for alternative designs to the standard battery packs.

Graphene is yet to be produced in sufficient quantities to be used for energy storage, but it could provide a new form of storage technology in the future.

Work with RatedPower to optimize your renewable plants. If you’re working on a solar power project incorporating battery storage, we’d love to chat! Our solar design platform provides optimum planning for solar installations and can help you maximize the capacity of your project.

Applications of BESS in a PV plant

The intermittent nature of solar and wind power generation means that renewable energy systems still depend on fossil fuel plants to fill the gaps. There are also times when potential generation is lost if there is too much for the distribution grid to handle and systems must be disconnected.

This is where battery energy storage systems (BESSs) are a game changer. BESSs create more flexibility and guarantee that renewable supply can be integrated into the system.

While much of the focus on BESSs has been on storing power for homes and power plants, battery systems serve multiple purposes in resolving various power system challenges. There are several important ways that grid operators can incorporate battery storage for more stable power supply.

Grid ancillary services

On occasion, electricity supply and demand become imbalanced — either the generation is not sufficient to meet consumption, or consumption is too low to absorb all the electricity on the grid. In these instances, the power system can become disrupted and events such as blackouts (power cuts) or brownouts (dips in voltage) occur.

Grid ancillary services help power grid operators to maintain power flows and balance the system. These include synchronization, contingency, and flexibility reserves, as well as black start regulation after blackouts.

Grids that integrate significant renewable generation sometimes require additional ancillary services to manage the higher variability and uncertainty in power supply.

BESSs can provide a range of ancillary services, such as demand response, congestion relief, voltage and frequency regulation, arbitrage, and peak shaving.

Frequency regulation

Grid operators must keep the alternating current (AC) within strict tolerance bounds by regulating consumption and output from generation plants on a second-by-second basis. Electrical grids transmit power from generation plants to users at a fixed AC frequency. This is typically 50Hz in Europe and Asia and 60Hz in the Americas. Frequency is stable when power consumption matches generation.

As more renewable systems are connected to the grid, variations in electricity output and fluctuations in frequency become increasingly frequent and severe.

Why is this important? If electricity usage is higher than the available supply on the grid, the frequency drops and causes brownouts or blackouts. When the electricity supply on the grid exceeds consumption, the frequency rises, which can cause damage to the grid as well as connected devices.

Battery storage systems are increasingly being used to provide frequency regulation services as their flexibility and fast response times — milliseconds in the case of lithium-ion batteries — make them better suited than fossil fuel plants.

Black start capabilities

Black start resources are used to resume stable supply after blackouts and must do so without a grid connection. Emergency backup systems are typically run by diesel generators or small industrial turbines run by fossil fuels. But BESSs are ideal for black start applications because they can run independently of the grid in standby mode. They can re-energize the grid in the event of an outage by resuming the flow of electricity to auxiliary systems without the pollution associated with diesel generators.

Voltage support

In addition to frequency regulation, grid operators must maintain voltage stability. What is voltage support and why is important? High solar PV or wind generation at times of low consumption can cause fluctuations in grid voltage. Generation units or static equipment that can produce or absorb reactive power provide voltage support to keep voltage within strict operational limits.

One challenge in providing voltage support is that reactive power can only be transmitted over short distances. BESSs offer an ideal solution as they can be located close to end users to inject and absorb reactive or active power into and from the power grid.

Energy arbitrage and load management

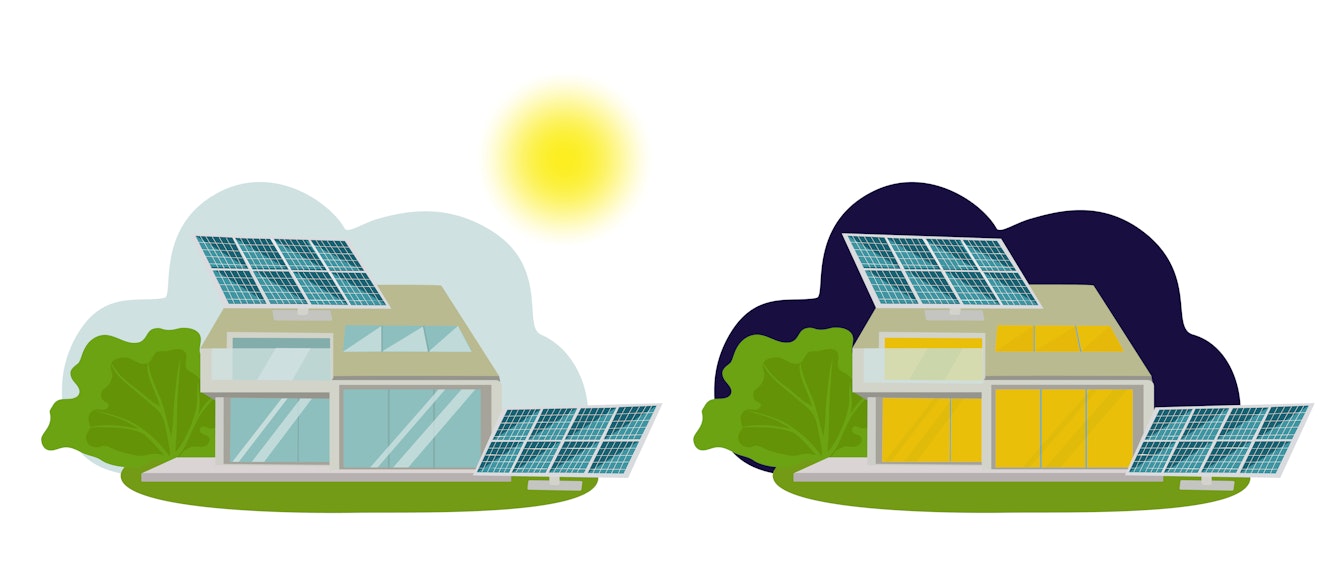

Peak-load shifting is one of the main advantages of battery storage for residential, industrial, and commercial users. But it also has an important role to play for power grids.

BESSs are charged when renewable output is high and there is sufficient supply on the grid to meet consumption, and then discharged when output is low or demand is higher and electricity costs increase. This helps end users manage their electricity bills. It also makes renewable supply — especially photovoltaic (PV) output — less intermittent and more stable by smoothing out supply throughout the day and night. Grid operators can reduce load on the system by shifting it from peak to off-peak hours.

Transmission resource management

Upgrading power grids with new transmission and distribution (T&D) lines requires extensive planning and capital expenditure. It takes years to bring new lines into operation, but addressing climate change requires new renewable capacity to be brought into operation rapidly.

The inadequate T&D capacity to handle renewable generation in some countries has resulted in supply losses as grid operators have had to turn off generators or refuse applications for new solar and wind farms. BESSs can provide alternative, cost-effective upgrade methods for T&D infrastructure because they are flexible, portable, and scalable.

Operators are increasingly using BESSs to supplement traditional T&D assets, replace inadequate or obsolete capacity or even eliminate the need to build new lines. By providing storage for excess generation and reserve capacity, BESSs can reduce the load on T&D lines and reduce congestion in transmission networks, maximizing their efficiency.

Microgrids

BESSs form an essential part of microgrids — distributed power networks that can be connected to the main T&D grid or run as completely independent systems. Microgrids are critical to bringing electricity supply to remote areas where grid operators are unable to build T&D lines because of terrain or budget constraints.

Renewable power systems integrated with battery storage can provide consistent power generation in underserved areas while eliminating the high cost and harmful emissions of diesel generators.

Microgrids with battery storage can also provide solutions when stable electricity supply comes under threat from climate change. They provide a resilient power supply amid increasing outages caused by extreme weather conditions and can even withstand hurricanes.

Latest stories

Related posts

Technology and engineering

Innovation in renewable energy: Developments expected in 2025

We look at the 10 biggest renewable industry developments that are making a green future possible, including perovskite solar cells, green hydrogen, and more.

Updated 18 MAR, 25

Market analysis

Breaking down solar farm costs: Free template inside

Updated 27 SEP, 21

Market analysis

Solar energy in Australia: a 2021 market analysis

Updated 11 MAY, 21

- RatedPower

- Solar energy blog

- The power of battery storage: Evolution and alternatives