- Solar energy blog

- The importance of meteorology in solar plant design & how to perform meteorology analysis

The importance of meteorology in solar plant design & how to perform meteorology analysis

Félix Pérez

Principal Software Engineer

Felix is a PV engineer and software developer, specializing in the development of calculation models and algorithms. After working in an engineering firm, he joined RatedPower to lead the development of the energy and topography calculation models of pvDesign, with a focus on building robust engineering software. Felix is enthusiastic about all disciplines of engineering, and enjoys discussing the more nuanced aspects of both. He is also very passionate about research, which has been a constant through his career in RatedPower.

Content

Solar photovoltaic (PV) plants have been an increasingly popular source of energy for the past years, as it is renewable and useful in many different conditions. That being said, the production of solar PV plants is deeply connected to the meteorology of the location of your plant.

Utility-scale solar PV plants are usually built on flat and open spaces, meaning they get directly affected by the meteorological conditions. Because of this fact, PV plants are built or not depending on factors like how much sunlight an area gets on an hourly interval per year, diffuse irradiance, soiling and snow.

Analyzing the meteorology of an area determines how much energy and sunlight can be used, or lost, in a particular area.

In today’s blog post, we will be looking into how solar developers take meteorology into account when designing projects to ensure maximum efficiency and best results.

What is a typical meteorological year (TMY)?

Input of the right meteorological data is crucial for solar plant design, as uncertainty in the data directly translates to uncertainty in the energy yield. This type of issue cannot be solved through any simulation model, only by inputting the right data.

But what is the right data? And how can you find it?

The meteorological data to analyze PV performance comes in the form of a typical meteorological year (TMY) which shows the meteorological data of a chosen area in (usually) hourly intervals.

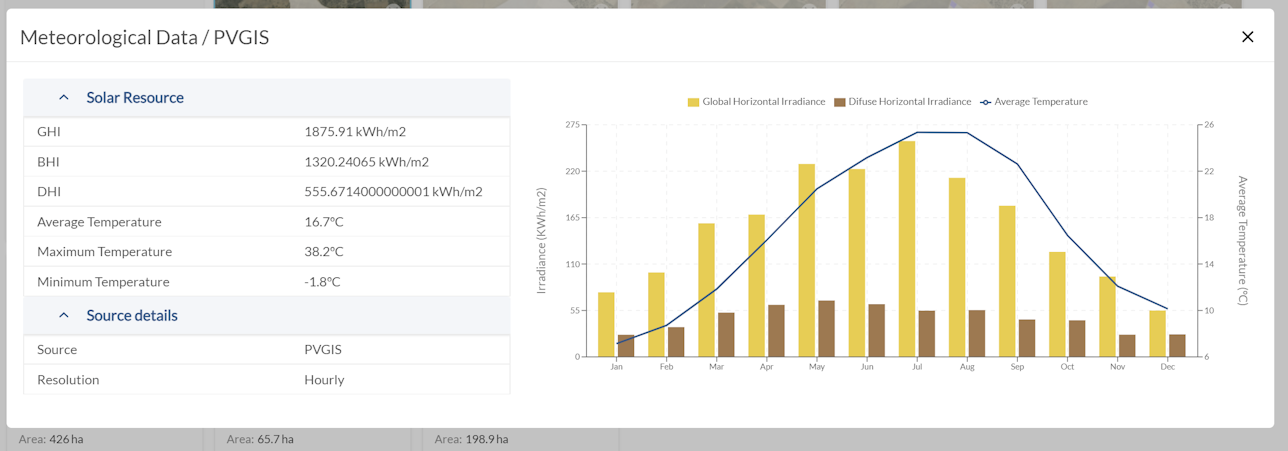

The hourly intervals of TMY reflect information on global horizontal irradiance (GHI), diffuse horizontal irradiance (DHI) or beam horizontal irradiance (BHI), and ambient air temperature. Additional information such as wind speed and albedo data can be added depending on the availability of the data and the design of the PV plant.

The data being analyzed over a year shows patterns that help to understand the characteristics of the typical weather in a location, as factors such as the presence of clouds which block the sunlight are implicit in the measurements of GHI and DHI.

An example to show this could be how cloudy weather has a much higher proportion of diffuse irradiance than sunny weather. Thus, TMY’s hourly intervals show how the diffuse radiation changes in a certain area through the rainy, the cloudy, and the sunny days.

The statistical uncertainty of a TMY changes depending on data source and location. For example, SolarGIS reports an uncertainty of ±4% for GHI in most of the world.

One important piece of data that isn’t included in TMY is soiling. Soiling is the accumulation of dust or dirt on the surface of the modules, which has an effect on the productivity of the PV plant. Furthermore, soiling can be variable depending on the seasons (for example, due to snowfall in winter) or if the location is prone to dust storms. If the modules are not cleaned regularly or the location is prone to dust storms or other adverse meteorological events, a higher soiling value should be set.

Find out the top four ways to clean solar panels.

Careful consideration of these issues and of the uncertainty in TMYs is of paramount importance to accurately assess the viability of a PV plant, and also to achieve a design with optimal performance.

How the meteorological data affects PV plant design

There is a complicated relationship between the electrical system design and the effects of the aforementioned characteristics of the PV module.

In order to estimate the energy production of a PV plant, a simulation must be carried out where all effects are taken into account. The interactions between the PV production and the inverter performance will determine the adequacy of the design, and will play a key role in assessing its economical viability.

Here are some of the factors to take into account while doing this process manually:

In a PV plant, the DC field is oversized with respect to the inverter. That means that, if the PV modules were to produce their nominal power, they would overwhelm the inverter and production would be wasted. To quantify this oversizing, the DC/AC ratio (which usually has a value of around 1.2) is used.

However, modules can’t realistically reach their nominal power, because it is measured in standard test conditions, which never occur in the field. In particular, the power is measured at a cell temperature of 25C, which is unrealistic for the conditions PV plants will be in. This means that a slightly oversized DC/AC ratio (of around 1.2) will rarely be overwhelmed by the PV module production.

Nonetheless, in locations with low solar irradiance, rainy climate, or very high temperatures, the ratio can be raised higher and still not overwhelm the inverters. This is because the modules are even more unlikely to reach their nominal power. And at the other end of the spectrum, locations with very high solar irradiance. One example of that could be the Atacama desert, which can require lowering the DC/AC ratio. At higher temperatures the inverter itself may be negatively affected, usually in the form of losing maximum output power.

Another important consideration is the interaction between the ambient temperature and the voltage of the module strings. At lower temperatures, the module voltage rises, and because of this the number of modules per string has to be adjusted so that the maximum voltage of the inverter is never exceeded. This effect is also considered in an energy simulation, taking into account the ambient temperature and irradiance conditions in every hourly interval.

Meteorogical data provided. Source: RatedPower

The benefit of automated solar design software

Solar software like RatedPower platform can optimize all the elements of a site design automatically, running calculations within minutes that could take days to do manually.

RatedPower can take the complicated relationship between the electrical system design and the effects of the aforementioned characteristics of the PV module, and give you the roadmap to a successful PV plant implementation.

RatedPower automatically obtains TMY data from 3 different sources to help you carry out a detailed energy yield analysis. The data is automatically used in the simulation, without needing to do any conversion or take additional steps.

Utility-scale PV projects don’t need to fall apart because of the intricacies of meteorological data analysis. Software automation can optimize the information of a location, saving time and money on costly adjustments to the terrain once the project is underway. This increases project profitability and makes it possible to develop installations on land that may not have seemed suitable in the past.

Take a look at how a PV plant planning software can automate the meteorological analysis for your solar project site.

Latest stories

Related posts

Technology and engineering

Innovation in renewable energy: Developments expected in 2025

We look at the 10 biggest renewable industry developments that are making a green future possible, including perovskite solar cells, green hydrogen, and more.

Updated 18 MAR, 25

Technology and engineering

What the future holds for the longevity and efficiency of solar panels

Tests done by the French photovoltaics group Hespul showed that the panels, installed in 1992, are still operating at an astonishing 79.5% efficiency. Read on to find out more.

Updated 4 MAR, 25

Technology and engineering

Concentrated solar: An unlikely comeback?

Once described as obsolete, the concentrated solar power market ballooned to $53 billion in 2023 and is still growing. Here’s why CSP is making a comeback.

Updated 12 NOV, 24

- RatedPower

- Solar energy blog

- The importance of meteorology in solar plant design & how to perform meteorology analysis