- Solar energy blog

- Practical Strategies to Minimize Energy Losses

Practical Strategies to Minimize Energy Losses

We recently held a webinar exploring the energy losses seen during the capture and conversion processes of solar PV modules. If you didn’t manage to catch the webinar or don’t have time to give it a watch now, we’ll be breaking down the key points and some practical tips and tricks we shared during the session.

If you are looking for the full webinar, check out the link here! If not, then read on!

Gorka Arrieta

Product Owner

Gorka is an energy engineer turned Product Owner at RatedPower, and brings three years of experience in the renewable energy sector. With a fervent dedication to sustainability, he concentrates his efforts on advancing energy storage solutions that keep up with the fast developing pace of the industry. In his less than a year tenure at RatedPower, Gorka endeavors to contribute meaningfully towards a greener future.

What are energy losses?

Let’s start by just briefly covering exactly what we mean by energy losses. In essence, energy losses refer to any energy lost by a PV module or installation due to factors in a real-world environment.

These losses can occur in a number of different ways, such as:

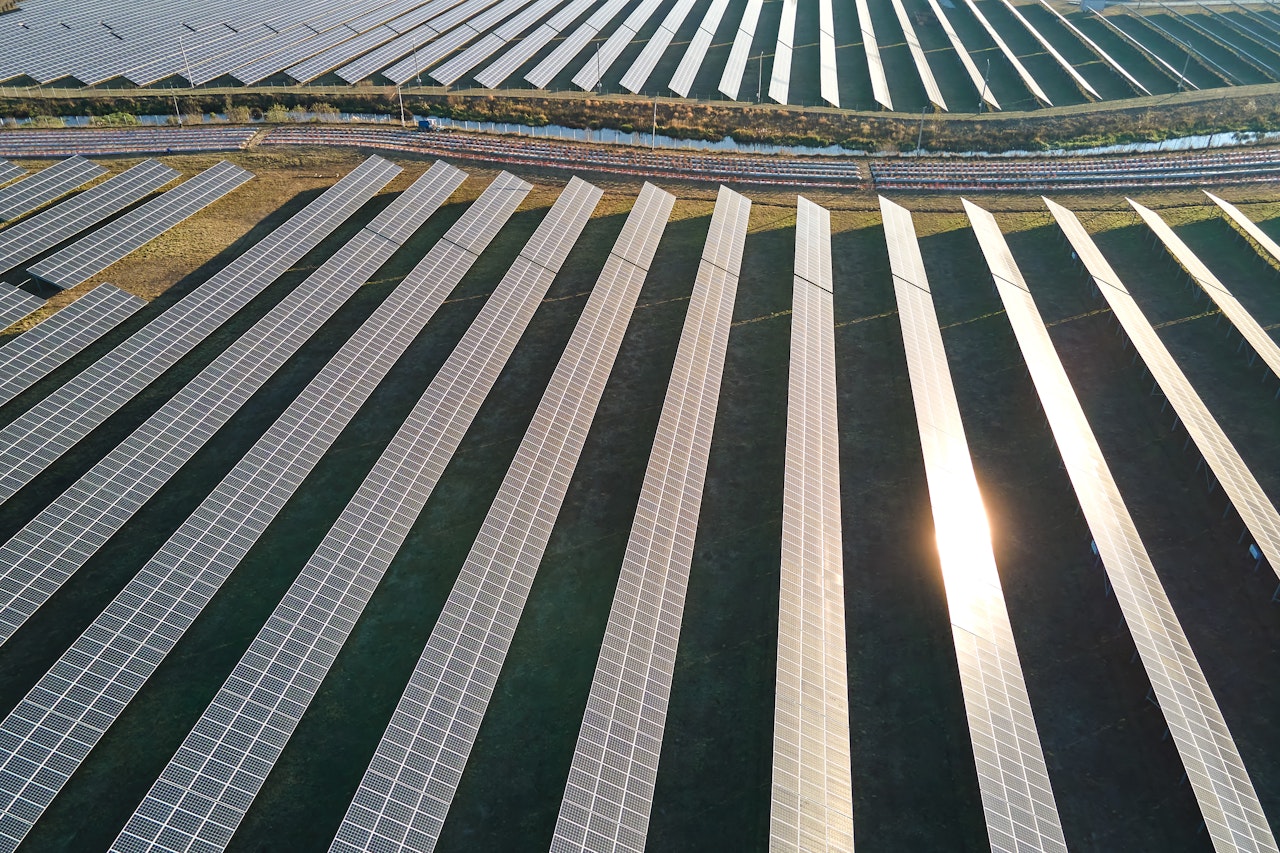

Shading losses — When panel surfaces are blocked from receiving sunlight due to obstructions such as other modules, foliage, or topography

Dust and dirt — If panel surfaces are dirty, less sunlight is able to reach the surface and be converted into electricity.

Reflection — Due to the design of solar panels, some sunlight is invariably reflected off of their surface and not converted into electricity

Spectral — Solar cells are unable to convert every wavelength of light found in sunlight into electricity, leading to losses when compared with irradiance level.

Irradiation — Panels in the real world are not operating under lab conditions and therefore experience some decay in the level of sunlight converted.

Thermal — Higher temperatures have a negative effect on solar cell efficiency, meaning the higher the temperature of the module, the greater the losses.

Array mismatch — Some panels will not produce as much electricity as other panels, leading to a mismatch in output levels. This can be caused by differing string lengths, shading, or slight differences in the cells.

DC & AC cable losses — Cable losses are inevitable but can be made worse by poor cable management, selection, and maintenance.

Inverter losses — Inverters tend to have very high efficiency but this can drop with higher temperatures or poor inverter selection.

If you want even more information about shading losses, the different types there are, and what you can do to minimize the shading losses of your next PV installation, download this eBook to find out!

How do we measure energy losses?

Measuring energy losses involves comparing the theoretical maximum output of a given installation with its actual output. The theoretical maximum is found under ideal lab conditions of 1000 W/m2 irradiance level and 25 degrees Celsius cell temperature. Actual output is measured by taking real-world factors into account. The difference between the theoretical and actual output of your installation tells you the energy losses that are being incurred.

In order to minimize the losses seen in utility-scale installations, these factors must be considered and planned around during the design phase. However, it can be difficult to know where to start when it comes to mitigating your potential energy losses.

So, let’s look at some practical strategies you can apply to your next installation.

Practical strategies

We can break down energy losses into three main categories: front-face losses, back-face losses, and electrical losses. The first two categories concern capturing losses — losses associated with the capture of sunlight by the panel face. Electrical losses concern the conversion process — losses associated with the conversion of sunlight into electricity.

We’ll discuss each in turn.

Front-face losses

These are exactly what they sound like — losses associated with the front face of the solar modules.

Both far- and near-shading losses fall under this category. There is little that can be done to mitigate far-shading losses beyond site selection due to their association with topography, however, rotating the azimuth of the structures can be beneficial.

Near-shading losses can be mitigated by keeping foliage and vegetation under control, back-tracking, terrain-following trackers, and choosing the right pitch and tilt angles of your structures to ensure neighboring cells are not shading one another.

Dust and dirt losses are also associated with the front face of the panels. When there is a buildup of dust or dirt on the module face, up to 10% of the output can be lost. For utility-scale installations, it is recommended that cleaning is carried out 1-2 times per year, depending on the site and the level of soiling.

Back-face losses

As with front-face losses, the name here is fairly self-explanatory — back-face losses are energy losses associated with the rear side of the modules. Note that these losses only apply if your installation uses bifacial modules.

Ground shading losses are often overlooked when modeling shading losses as they are only found on the back side of bifacial modules. Shade cast by the structures prevents sunlight from being reflected from the ground and shades parts of the cells themselves, leading to a loss in irradiance and output.

To mitigate this, increase the distance of the modules from the ground to minimize shading, as well as keep vegetation and foliage under control.

Electrical losses

These losses occur during the conversion of sunlight into electrical energy. They are typically more complex to solve and can come in a variety of forms.

Module degradation is one of the most common causes of electrical losses. Over time, modules naturally degrade and become less efficient. This is an unavoidable process but large temperature swings, high salinity, rain, and ambient humidity can all hasten the degradation of PV modules. Likewise, regular maintenance and cleaning can help slow the rate of degradation.

As mentioned earlier, higher temperatures lead to increased losses. It is again difficult to mitigate high temperatures beyond site selection but the presence of water in a floating PV station, and the exposure to wind in agrivoltaics may help cooling modules in the future.

Mismatch losses can occur for multiple reasons but also have multiple fixes. When designing a PV installation, it is important to group modules by quality, avoid partial shading, and design your installation in a homogenous way in order to minimize mismatch losses.

Although similar to the other forms of shading losses discussed, array shading losses occur because the current of a module can only be as high as the lowest current of each module connected in series. This can be mitigated through the use of thin-film modules and following the other shading tips above to ensure maximum irradiance on all modules.

Cabling losses are another form of energy loss that is unavoidable — some energy will always be lost during electrical transmission. However, choosing the correct cabling based on the amount of power that is being transmitted, as well as picking the right material for your cables, will help minimize this.

The same is true for inverter choice. There is no one-size-fits-all for inverters and selection should be based on the specifics of your installation. That being said, it is important to choose a balanced DC/AC ratio for your inverters.

Hopefully, this has given you a few tips for how you can minimize energy losses on your next utility-scale installation. Again, if you are looking for more information and depth on any of these types of losses and how to combat them, make sure you watch the webinar here.

RatedPower gives you the tools to design your next project and has an array of features for modeling and minimizing energy losses. Get in touch today and take your plant design to the next level!

Latest stories

Related posts

Technology and engineering

Innovation in renewable energy: Developments expected in 2025

We look at the 10 biggest renewable industry developments that are making a green future possible, including perovskite solar cells, green hydrogen, and more.

Updated 18 MAR, 25

Technology and engineering

What the future holds for the longevity and efficiency of solar panels

Tests done by the French photovoltaics group Hespul showed that the panels, installed in 1992, are still operating at an astonishing 79.5% efficiency. Read on to find out more.

Updated 4 MAR, 25

Technology and engineering

Concentrated solar: An unlikely comeback?

Once described as obsolete, the concentrated solar power market ballooned to $53 billion in 2023 and is still growing. Here’s why CSP is making a comeback.

Updated 12 NOV, 24

- RatedPower

- Solar energy blog

- Practical Strategies to Minimize Energy Losses