- Solar energy blog

- A look into the US photovoltaic manufacturing boom

A look into the US photovoltaic manufacturing boom

The US is in the midst of a solar manufacturing boom. Explore the reasons why and learn how this exploding industry can benefit us all.

Gabriel Cañadas

Tackling the climate crisis has become a priority for countries and governments the world over. No longer can the issue be pushed down the road, but drastic action must be taken now in order to prevent the damage from becoming irreversible.

To this end, many countries have been investing in renewable and clean energy solutions, passing legislation to drive the adoption of green technologies, and taking steps to move away from using fossil fuels. One such country is the US, which has been making tremendous strides in the solar photovoltaic (PV) sector in recent years.

In this blog, we’ll look at why the US is performing so well on the global solar stage and how the country has become a hub for PV manufacturing.

The US solar market

Before we go into specifics, let’s first have a quick overview of the US solar market as a whole. After a slightly slower year in 2022 due to supply chain issues and shortages, the US has bounced back in stunning fashion in the first two quarters of 2023.

In Q2 alone, the country installed 5.6 GW of solar capacity and expects to install a total of 32 GW by the end of the year. This would not only be a record but would represent a 52% increase over 2022.

In addition, the solar PV market hit record highs in 2023, partly due to the skyrocketing gas prices. The average value of solar projects, based on local electricity prices and capacity values, increased by 40%, while the average cost of utility-scale project installation continued to decrease.

From a manufacturing perspective, the US still relies heavily on Southeast Asia to supply its solar modules and cells. Despite having the manufacturing capacity to produce a range of crucial materials needed for solar modules (such as aluminum, metallurgical grade silicon, and steel), there are still substantial gaps in the PV supply chain.

The US’s insufficient capacity to produce wafers, ingots, solar specialty glass, and cells still leaves them dependent on imports. Filling these gaps will form the basis of the US manufacturing resurgence with an expansion of the capacity of polysilicon, making it more competitive on the global market.

In the short term, the US will still need imports to ensure the national energy supply is unhindered. However, the solar industry predicts a bright future of increased investment and exponential expansion over the coming years. So much so that there are predictions that solar manufacturing jobs could increase threefold by 2030 to 115,000, boosting the total manufacturing jobs to 507,000

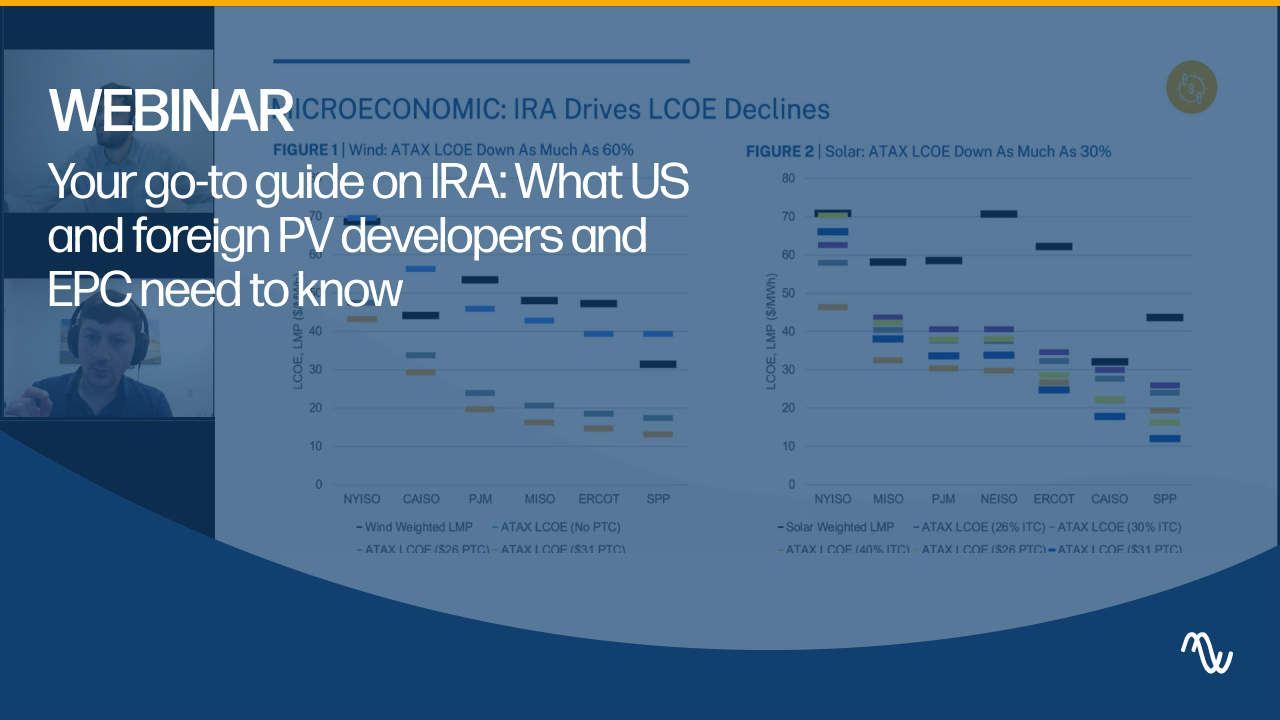

What is driving this boom? Let’s look at one of the key influences behind the US PV manufacturing upturn, the Inflation Reduction Act (IRA), which is playing a vital role in this success story.

The Inflation Reduction Act

Much of this US solar PV market growth can be attributed to the Inflation Reduction Act (IRA). This act has multiple aims, including funding green energy projects, lowering healthcare costs, and taxation adjustments.

As it pertains to renewable energy, the IRA has multiple provisions designed to incentivize private investment and bolster new and existing projects. Some of these provisions include:

Roughly $400 billion of federal funding for green projects

$12 billion to upgrade, repurpose, and replace energy infrastructure

Tax credits to incentivize private investment in the renewable energy sector

$43 billion in tax credits to lower consumer emissions

The support and financing from the IRA have helped the US to drive the green energy transition forward. And much of these efforts are coming in the form of solar PV manufacturing and production. It is expected that the IRA will facilitate the installation of 950 million solar panels, 20,000 wind turbines, and 2,300 grid-scale battery facilities, all by 2030.

IRA’s effect on the US PV manufacturing boom

As mentioned above, for many years, solar PV manufacturing has been dominated by China. In fact, China produces roughly eight out of every ten solar panels. And while China is still the world leader in PV manufacturing, other countries are beginning to catch up.

In the wake of the IRA, there has been over $150 billion of investment into US-based utility-scale clean power projects, translating into over 96 GW of clean energy capacity once these projects are complete. Underpinning this is an increase in the manufacturing capacity of some of the key areas of the supply chain. This includes a manufacturing capacity expansion of:

16GW for ingots and wafers

9 GWac of inverters

16 GW of cells

47 GW of new modules

100 GWh of battery (which also supplies the EV industry)

According to the American Clean Power Association (ACP), from a total of 46 new utility-scale clean energy manufacturing facilities, 26 will manufacture solar PV modules and technologies. These new facilities are estimated to create over 18,000 new jobs for Americans and significantly bolster local economies.

The largest site that has been announced is the Qcells facility in Georgia. Qcells, a subsidiary of Hanwha Solutions, announced that it would be investing $2.5 billion into a solar manufacturing facility in the US.

What makes this project different is that the facility will be a complete solar supply chain manufacturer, the first in the US. The facility will manufacture 3.3 GW of solar ingots, wafers, cells, and finished modules and assemble a further 2 GW of modules at a secondary site. By 2024, the facility is expected to have a total capacity of 8.4 GW and have created 2,500 jobs.

While this is the largest new facility, it is by no means the only one that has been announced after the passing of the IRA. Three of the largest solar companies in the world have shared plans to build factories in the US that will add a total of 15 GW of manufacturing capacity.

Trina Solar announced plans to invest $200 million into a 5 GW manufacturing plant in Texas. This project is projected to be in operation by 2024, manufacturing solar modules and creating roughly 1,500 jobs for local people.

Canadian Solar also has plans for a 5 GW facility in Texas. The facility has an expected investment of $250 million and will also manufacture solar modules, creating a similar number of jobs to the Trina plant.

Finally, Longi has partnered with utility-scale developer Invenergy on plans for a 5 GW facility in Ohio. The partnership has invested $600 million into the facility that will focus on solar panel assembly. The site is expected to begin operations by the end of 2023, with over 850 new jobs estimated to be created.

With the tax incentives provided by the IRA, plus the strong culture of manufacturing and innovation present in the US, the future looks bright for the country’s renewable energy efforts.

SEIA’s goal and vision is for the US to become the most collaborative and competitive solar and energy storage player globally, powered by its manufacturing capabilities. With continued investment and support, the US can not only become a solar manufacturing leader but also help drive the transition to green energy and address the climate crisis for the rest of the world.

If you’re looking for more solar PV news and insights, look no further than the RatedPower resources page! Packed with ebooks, reports, and webinars, we’ve got everything you need to know about solar and renewable energy.

Latest stories

Related posts

Technology and engineering

Solar Power Technologies that rocked it in 2022

28 Oct, 21 | Updated 14 Nov, 22

Technology and engineering

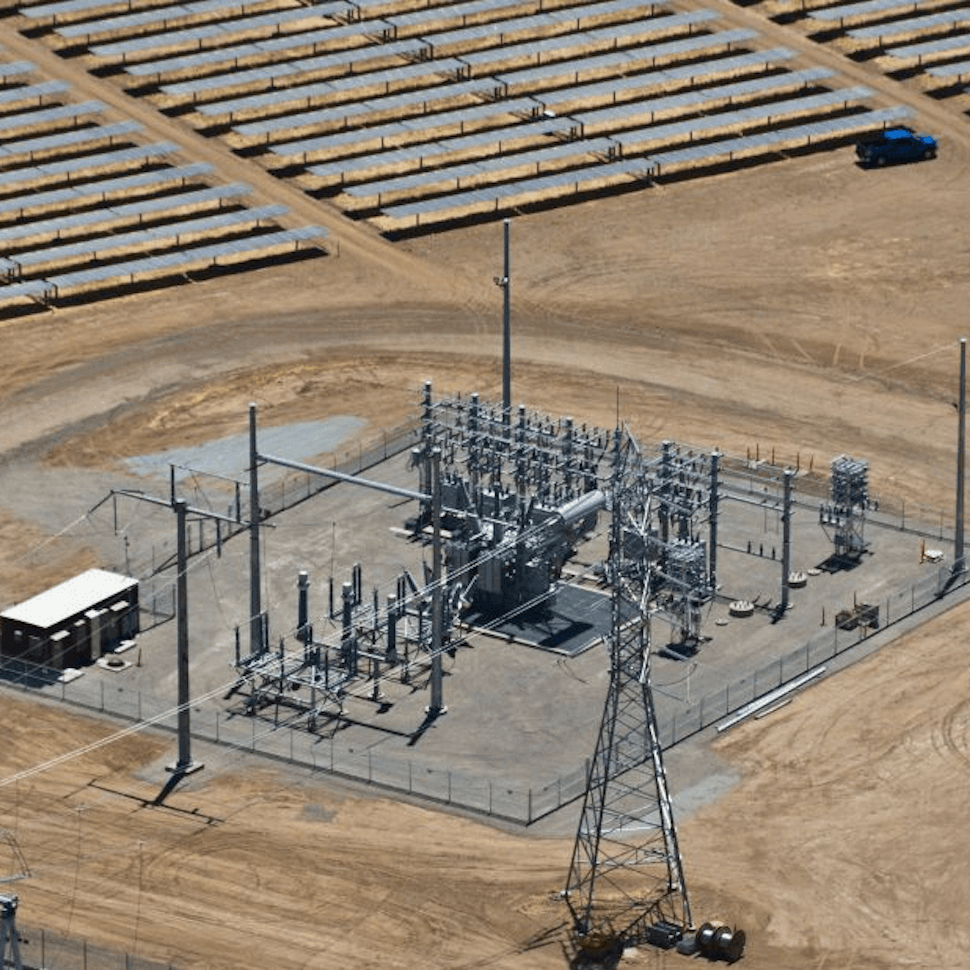

Learn PV substation engineering and design automation with RatedPower

Do you know why and how a solar farm connects to the grid? RatedPower automatically generates the best solution for an interconnection facility and chooses between a switching and breaking station, a line to transformer substation or a single/double busbar substations.

2 Dec, 21

Market analysis

Breaking down solar farm costs: Free template inside

4 May, 21 | Updated 27 Sep, 21

- RatedPower

- Solar energy blog

- A look into the US photovoltaic manufacturing boom