- Solar energy blog

- Choosing PV structures: Trackers vs Fixed vs East-West (Case study inside!)

Choosing PV structures: Trackers vs Fixed vs East-West (Case study inside!)

Bernardino Martin

Product Owner

Bernardino brings over two years of expertise to RatedPower, serving as Product Owner in the Product department. Previously excelling as a Customer Success Manager focusing on diverse markets where he developed a keen understanding of those market needs. Leveraging this experience, he now serves as a dedicated Product Owner, enhancing software solutions. Holding a Degree in Energy Engineering and a Master's in Industrial Engineering, Bernardino seamlessly combines technical prowess with a customer-centric approach, contributing to the ongoing innovation and advancement of renewable energy solutions.

Content

Adapting the structure of a solar photovoltaic (PV) installation to its geographic location and terrain is key to maximizing two important factors: the amount of energy it can produce and balancing costs with output. This becomes more important with utility-scale plants as it affects the amount of return on investment a project can generate.

There are three main types of mounting structure for solar module design. In this post, we look at each one and how they work at two plants in Europe. Find the whole engineering documentation for each project at the end of the article.

Get the 300 pages of technical documentation for each structure type. Download sample documentation.

PV plant structures explained

The mounting structures that support solar PV panels can be fixed in place or they can include a motor to change the orientation of the modules to track the sun. There are advantages and disadvantages to each design depending on the project.

Trackers

Horizontal single axis trackers (HSAT) rotate on a single fixed axis with motor-powered tubes. The PV panels are mounted on the tubes, which rotate from east to west on a fixed axis throughout the day to track the movement of the sun across the sky and maximize solar generation.

Benefits

Tracker structures create higher power generation as they keep panels at the optimal angle to receive the most sun rays during the day — meaning that for the same peak power an installation can generate more energy. They also have an overall lower levelized cost of electricity (LCOE), despite requiring higher capital expenditure, as the increased efficiency reduces the cost of the electricity produced.

Watch-outs

While the greater number of PV modules you have placed in a tracker the more cost-effective your project will be, this creates long rows of trackers that are not suitable for sites with limited or irregular space. Single-axis trackers also have limitations in sites with undulating terrain or uneven sloping.

In some places, the geotechnical conditions at a site can make single-axis trackers unfeasible, as they require large foundations to accommodate wind loads.

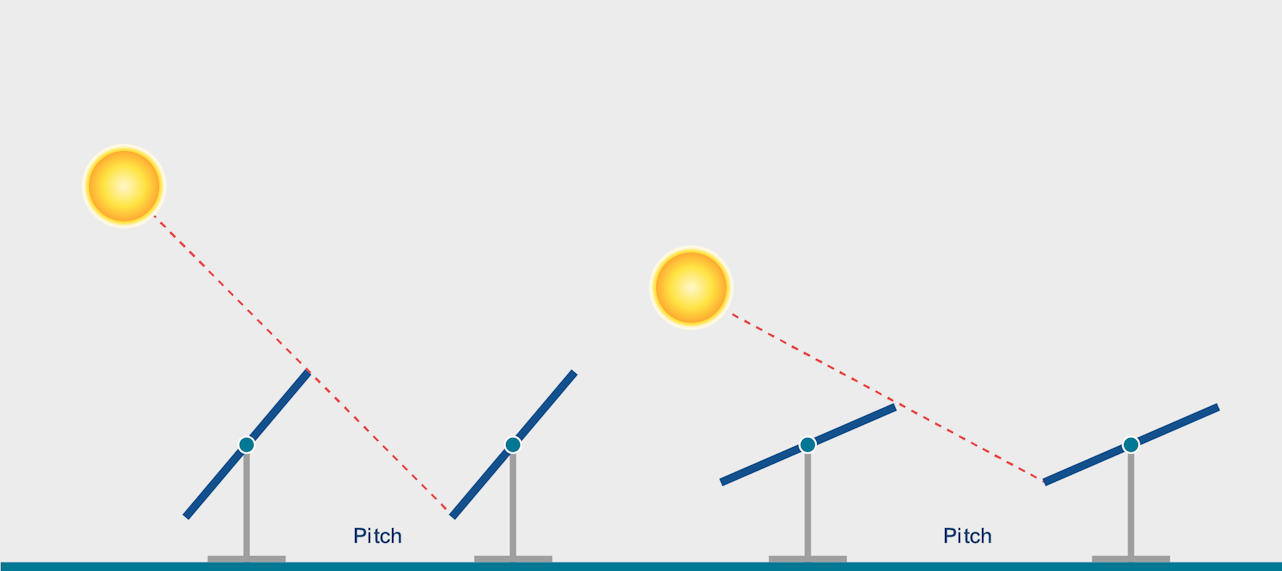

For sites that require low pitch with a high power capacity, some of the benefits of trackers are lost by the backtracking algorithms.

Fixed

Rather than using a tracker structure that adjusts the angle of PV panels to follow the sun during the day, a fixed-tilt structure angles panels towards the equator, so the angle depends on the latitude of the site. Panels are tilted towards the south in the northern hemisphere and towards the north in the southern hemisphere.

Benefits

Fixed structures allow more peak power to be installed than trackers, providing more total energy for the same area despite the lower specific production (kWh/kWp) especially during the morning and evening.

Taking into account the shading between rows created by the tilt of the panels, fixed structures can reduce the pitch distance by installing more rows and increasing the amount of peak power and total energy generated. Fixed panel designs can be tailored to fit the highest quantity of panels at each site.

Watch-outs

As more solar PV is installed and the power generated is injected into the grid in the central hours of the day, it causes the market price of energy to fall sharply, cannibalizing its own profit. Trackers lessen this risk by spreading their generation over the morning and evening.

East-West

In east-west systems, solar panels are installed with half of them facing towards the east and half facing towards the west.

Benefits

Panels can be placed back-to-back to reduce the space between rows and allow for more modules to be installed to increase power generation. This is ideal for regions such as northern Europe, to maximize output from sites that have limited space.

When facing tricky terrains, having high detailed topography data is key for ensuring bankability and accurately bidding your solar project. Learn how to leverage drone data and load it into RatedPower in this session. Watch it now.

East-west structures also tend to be used more at higher latitudes as the sun does not rise as high in the sky and panels can be placed closer to structures without shading, generating more energy from the same area.

As east-west systems are installed lower to the ground, they reduce wind loads on the panels as winds pass over the array. And as they produce energy at a stable rate throughout the day, they reduce the chances of the inverter becoming overloaded by a midday spike.

Watch-outs

East-facing and west-facing panels need to have separate electrical systems, requiring a different layout and site analysis from traditional configurations. And as there is less space between each panel, performing maintenance is more difficult than with a tracker system.

The large amount of modules installed that are operating outside its optimal angle causes the specific production of the PV (kWh/kWp) plant to drop and the total cost of the PV plant to increase, thus increasing the LCOE ($/kWh).

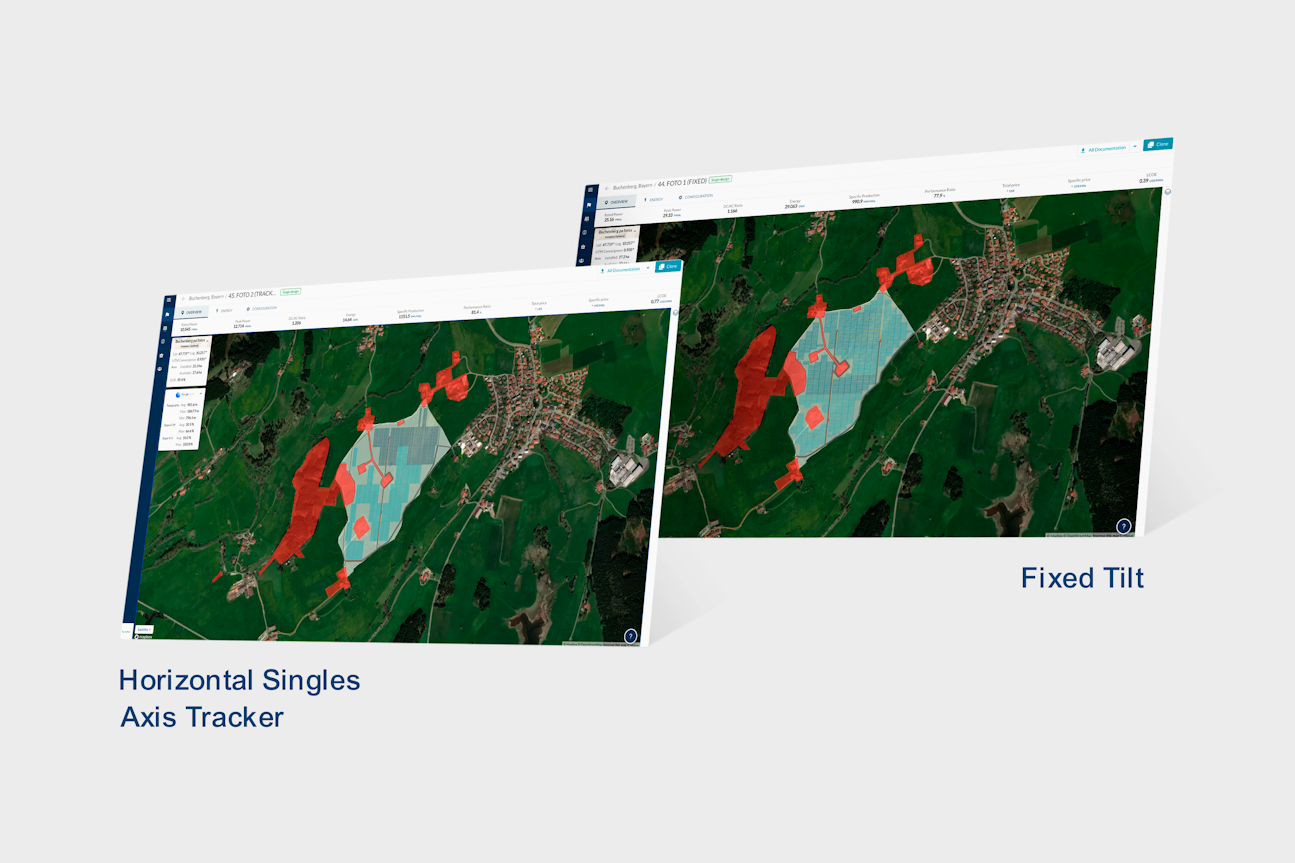

Comparing PV structures: a RatedPower case study

A comparison of sites designed and analyzed by RatedPower shows that the cost of the land in relation to the cost of the models, the cost of tracking equipment, and the actual energy output are all important factors when choosing a PV structure.

In Germany, for example, PV plant sites tend to be relatively small, so projects will use fixed or east-west structures that can install more power and deliver more energy versus tracker structures that occupy more space. East-west structures are also useful at higher latitudes, so projects at northern latitudes that need to generate a certain amount of electricity from a small site will tend to favor fixed or east-west structures. Projects that have more available space and focus on efficiency rather than specific power output would tend to use trackers.

The analysis shows that in Germany, tracker structures had a lower LCOE but generated 43% less energy — so while efficiency increased, the total output was lower. Specific price (€/kWp) was also higher for tracker structures than for fixed structures. East-west structures had higher costs and lower efficiency, as the panels do not face the south or the equator.

The good ol’ times of unlimited available areas for greenfield PV projects are gone with the wind. Hilly terrains are common nowadays —and earthworks are more needed than ever. Learn how solar developers can face the challenge of topography using software in our webinar. Watch it now.

We see similar results in Spanish projects regarding peak power, efficiency, energy production, and LCOE for the different structures — generating more energy at a lower price. But land costs are lower in Spain versus Germany, giving projects the freedom to use structures that take up more space.

Use RatedPower to plan your PV project structure

The structure of a utility-scale PV installation has a bearing on the energy efficiency, output, and revenue it generates. The most appropriate structure to get the highest returns will depend on the conditions of each project, with the cost of the site area and its latitude among the important considerations.

RatedPower platform can help you to automate the design of your project’s structure to find the best layout and maximize the return on investment.

Webinar: The optimal solar panel tilt to boost PV projects’ performance

Are you looking for ways to optimize tilt angles in your PV projects for maximum efficiency? Our Product Owner, Bernardino Martín, will guide you through the impact of choosing the optimal tilt angle and pitch distance for fixed structures in this upcoming webinar.

Latest stories

Related posts

Technology and engineering

Outsmarting congestion: How efficient solar design helps navigate Nordic grid limits

Learn how Nordic operators and solar developers are adjusting to tighter grid conditions and how policy and design decisions are keeping projects on track.

Updated 16 DEC, 25

Technology and engineering

The rise of ultra-thin perovskite solar cells

Learn about Japan’s $1.5B initiative to commercialize ultra-thin, flexible perovskite solar cells and how it could transform the solar landscape globally.

Updated 30 SEP, 25

Technology and engineering

The green hydrogen boom in LatAm

Latin America is emerging as a green hydrogen leader. Learn how LatAm countries are leveraging solar and wind power to drive green hydrogen production.

Updated 22 JUL, 25

- RatedPower

- Solar energy blog

- Choosing PV structures: Trackers vs Fixed vs East-West (Case study inside!)

Watch a demo

Watch a demo