- Solar energy blog

- Insights into the solar supply chain for 2023 and beyond

Insights into the solar supply chain for 2023 and beyond

Gabriel Cañadas

Content

Our lives depend on energy, from powering our homes and our cars to the electricity required for life-saving medical machines. As demand for this valuable resource grows annually so does the need for a reliable supply chain to ensure uninterrupted delivery of supplies.

But what exactly is the solar supply chain? Who are its players? And, most importantly, what will it look like in 2023 and beyond?

Who is involved in the solar supply chain?

The solar supply chain is made up of a number of different players. This ranges from manufacturers, installers, and financiers, to maintenance crews, technology integrators, and regulatory agencies. Each of these players contributes to the overall workings of the supply chain in their own way.

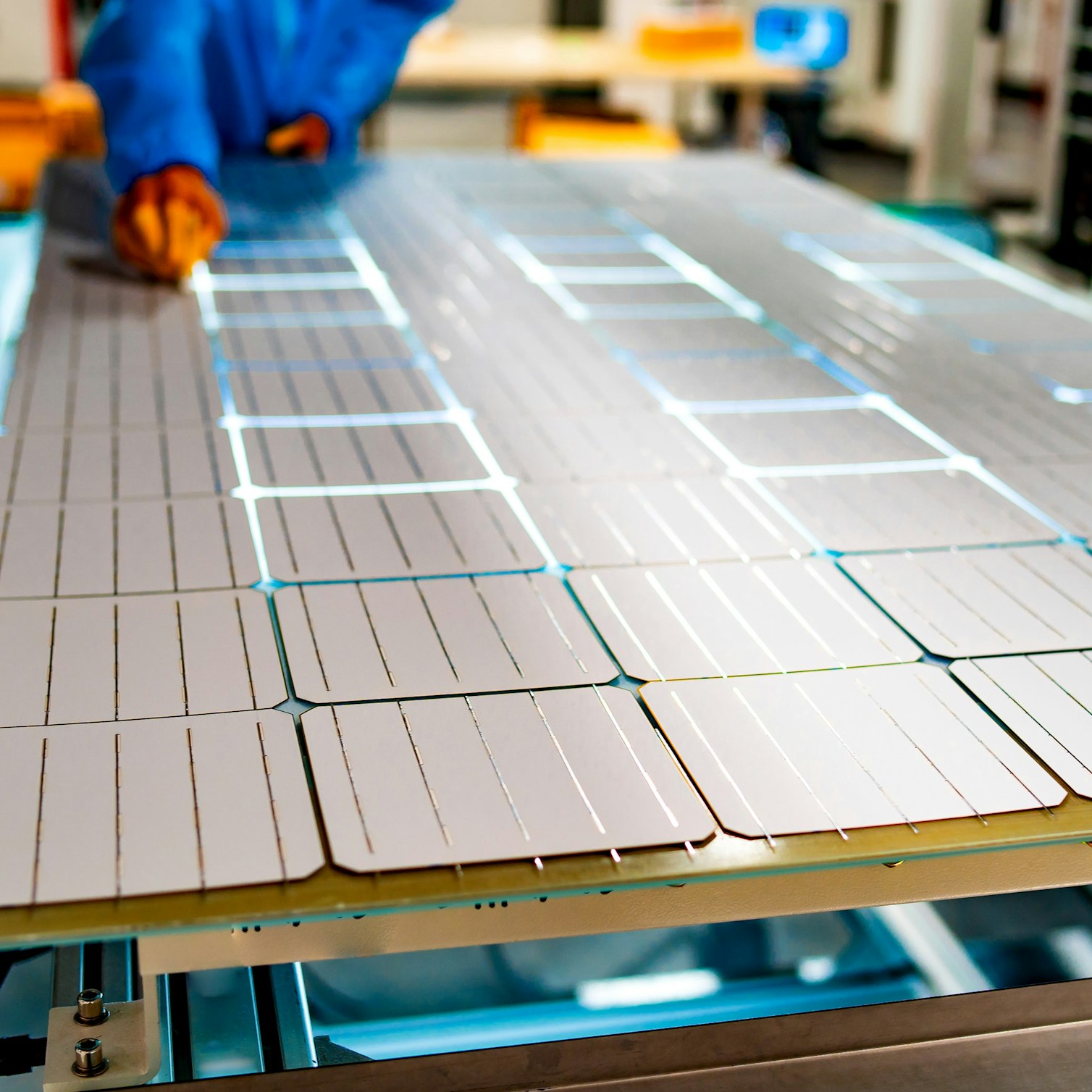

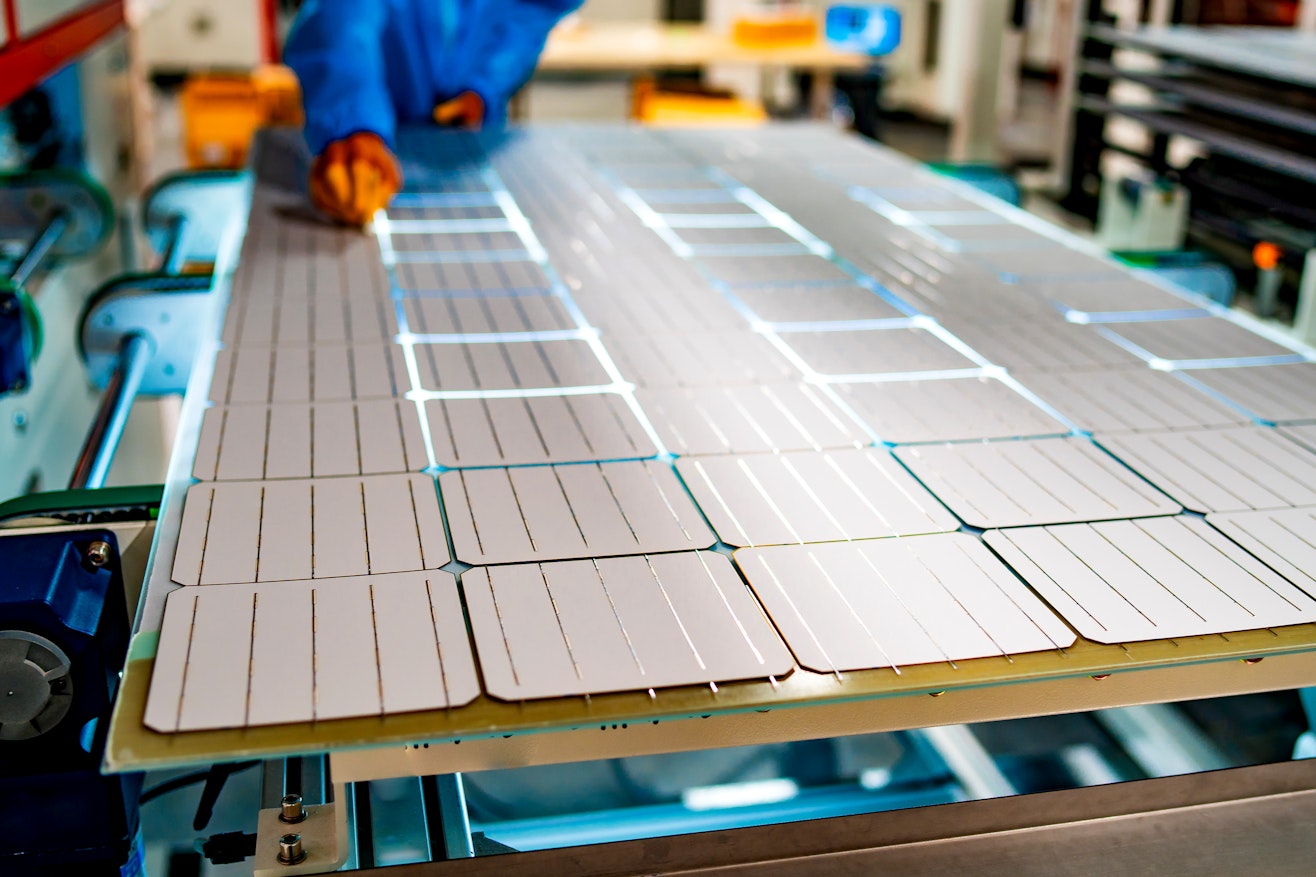

Manufacturers are responsible for producing the solar panels, parts, and components that make up the entire system. Installers, on the other, hand play an essential role in connecting all of these pieces together.

Financiers provide capital for businesses looking to purchase or build new solar systems and maintenance teams ensure that any issues with the system are dealt with promptly.

Technology integrators then consult on how best to integrate a solar system into an existing network, and finally, regulatory agencies oversee all aspects of solar development, installation, and maintenance to ensure it meets the necessary safety standards.

China’s place in the global solar supply chain

The Chinese solar energy industry is a major player in the global solar supply chain. In fact, as home to the top five companies across each step of the value chain, China produces nearly 95% of all solar wafers.

Initially, it was European countries that led the charge in the solar value chain, but today China dominates the sector, having increased its capacity from zero to over 300 GW in 15 years. With large-scale positions and a huge share of market across the entire value chain, China currently controls both manufacturing at scale and the rolling out of new technologies.

The challenge of China's monopoly

The challenge with Chinese companies dominating the solar value chain is that they essentially have a monopoly on the market. Specialized companies throughout China have the ability to deliver a wide variety of materials that are crucial in the solar supply chain. As a result, this solar production hub has driven the price of renewable energy technology down in multiple markets.

In fact, since 2010 the levelized cost of energy (LCOE) has decreased by 80%. Considering that LCOE is essentially the lifetime cost of solar PV, including both operating and capital expenditure, this has a significant impact on the global solar supply chain. For other markets, such as Europe, this drop in costs can be beneficial, but it also creates a reliance on the Chinese supply chain.

This is where the challenge comes in and is exacerbated by the Ukraine conflict and the production of polysilicon, a key raw material in the solar PV supply chain. The conflict taking place in Ukraine has unearthed a big risk that Europe faces as it relies on imports for critical energy. Then, when it comes to the production of polysilicon, labor concerns have added extra distress to the European market due to human rights issues as well as ESG-related matters.

Overcoming the challenges and the monopoly

In order to overcome these challenges, countries outside of China need to build far more diverse solar supply chains. This means that these countries should look to increase their investments in local manufacturers, focusing on improving production efficiency and reducing costs via innovative technologies.

By investing in local solar manufacturing, countries can help to reduce their reliance on imports and create a level playing field for alternative suppliers. This is especially important as the solar industry continues to grow and companies look to benefit from economies of scale.

European companies are beginning to respond

In light of the ongoing challenges, European companies are starting to respond and have been making strides in the direction of increasing their local solar production.

Solar production expansion plans are in play throughout Europe, with companies in Turkey, Sicily, Switzerland, Norway, Germany, and the UK making progress by increasing production and slowly forming a key component of the global supply chain.

The good news for these businesses is that only a few Chinese solar PV companies have entered the manufacturing race in Europe. They will however have to keep a close eye, as Chinese companies would bring both capabilities and already-scaled production systems to the region.

The solar supply chain in 2023 and beyond

The outlook for 2023 is still uncertain, but the solar industry outside of China is continuing to increase production, deliver cost-effective solutions, and drive renewable energy adoption across the world.

It is clear that the European market has a challenge ahead of it, but with the right investments and strategies in place, there's no reason why it can't build on its current local production capabilities and join China as a major player within the global solar PV supply chain.

The key to success will be in creating a competitive landscape that allows European manufacturers to compete with Chinese companies on cost, quality, and sustainability. This will certainly be an exciting space to watch.

Competition to find and hire the best candidates is becoming fiercer by the day. How can solar companies succeed in hiring the best solar engineers? Find out with our free eBook!

Improve your solar PV strategy with RatedPower's green energy market reports and resources

Download our collection of expert solar insights and industry trends to discover the latest solar and green energy information, as well as the smartest way to design utility-scale solar PV plants.

If you would like to find out how we can help your business plan, design, and optimize the PV plant engineering process, contact us today at +34 687 692 530 or send us your contact details and an experienced member of our team will be in touch.

Latest stories

Related posts

Technology and engineering

Innovation in renewable energy: Developments expected in 2025

We look at the 10 biggest renewable industry developments that are making a green future possible, including perovskite solar cells, green hydrogen, and more.

Updated 18 MAR, 25

Market analysis

Breaking down solar farm costs: Free template inside

Updated 27 SEP, 21

Market analysis

Solar energy in Australia: a 2021 market analysis

Updated 11 MAY, 21

- RatedPower

- Solar energy blog

- Insights into the solar supply chain for 2023 and beyond