- Solar energy blog

- Cabling solar installations for maximum efficiency

Cabling solar installations for maximum efficiency

Álvaro Pajares

Industrial Engineer

Born in Córdoba and raised in El Puerto de Santa María. Moved to Sevilla to study my Bachelor's and then to Madrid to study my Master´s (Industrial Engineering). During my Bachelor's I spent one year in Padova, Italy (where I learnt about Photovoltaics and how to cook the real pasta carbonara and risotto) and during my Master's I spent one year in Tampere, Finland (where I learnt how to live without sunlight). After coming back from Finland, I joined RatedPower!

Content

Spain’s renewable energy sector has been growing rapidly and the country has installed around 3.8GW of solar photovoltaic (PV) capacity in 2021, up slightly from 3.5GW in 2020, according to the latest EU Market Outlook from industry association SolarPower Europe.

Nearly 3GW was realised from power purchase agreement (PPA) based systems “out of a gigantic pipeline under development in Spain'', according to the report. “This makes the Southern European country probably the world’s largest market for subsidy-free solar, but it also demonstrates that grid constraints can be a major burden for rapid deployment of large solar volumes.”

The rapid growth of renewable energy is presenting challenges for the power grid in maintaining stability —especially for those working in early-stage projects like electrical engineers and developers.

Over this article we'll look at:

The role of cabling as PV losses minimizer

Types of solar cabling

How to group cabling to optimize your design

Our stake on this —and how our design and engineering solar design tool, helps

PV cabling and its role in reducing losses

To get the most out of a solar installation in other geographies with constrained grid access or topographical restrictions, you should consider that the way photovoltaic solar cables are wired affects the performance of an installation as well as the ease of access for monitoring and repair of the system. You want to reduce cable lengths as much as is practical to reduce energy losses and find the best position for convenient maintenance.

What are shading losses in a solar energy system? What causes shading? How can RatedPower help to account for them in a solar project? Check how limit shading losses to optimize solar LCOE.

There are different ways to wire solar panels effectively, whether in parallel or in a series. Using a string inverter rather than a central inverter also affects the way that panels are wired.

With solar panel wiring affecting the electricity output of the system, choosing the right configuration is essential to maximizing your return on investment. Let’s look at the different types of cables as well as the cabling structures suitable for large-scale solar plants.

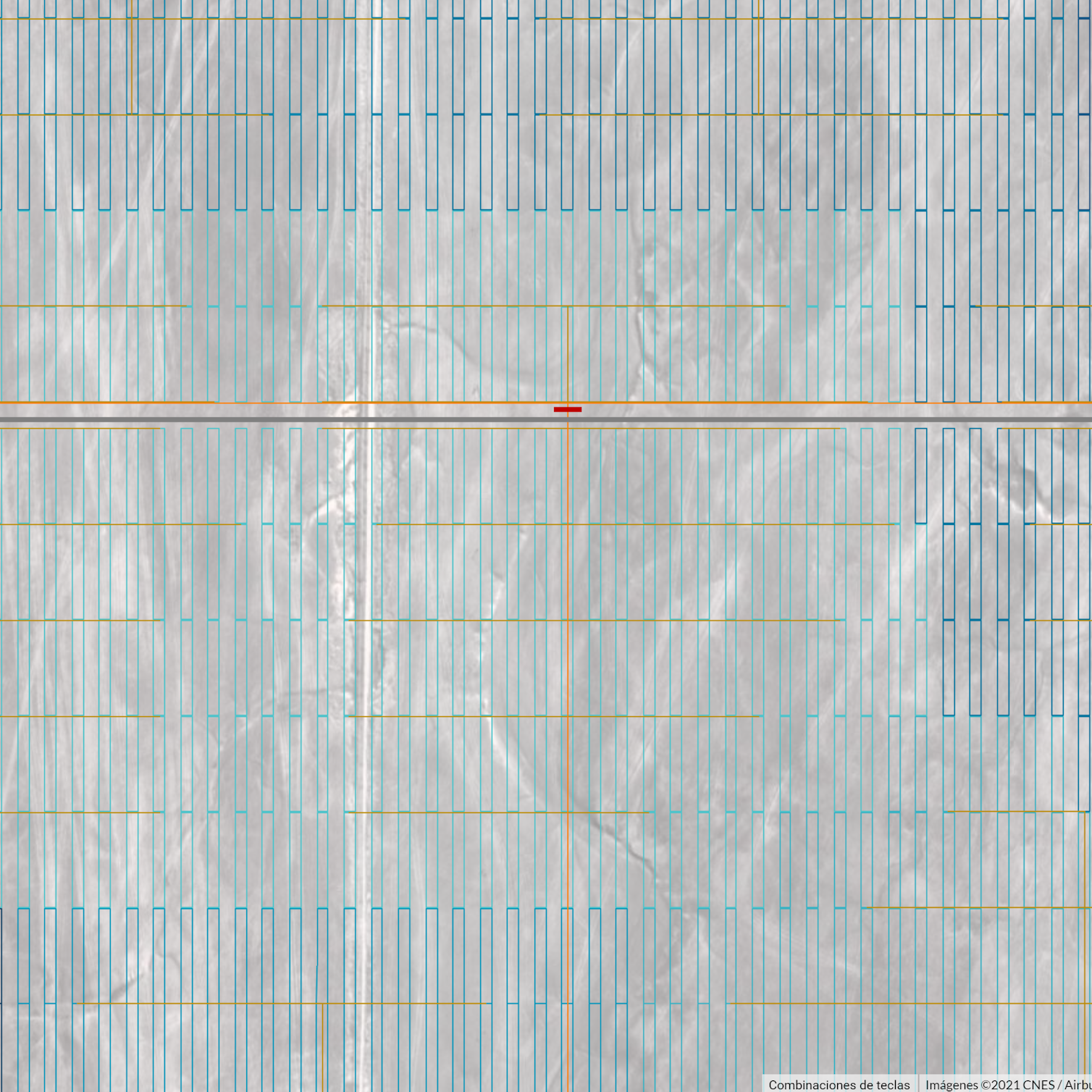

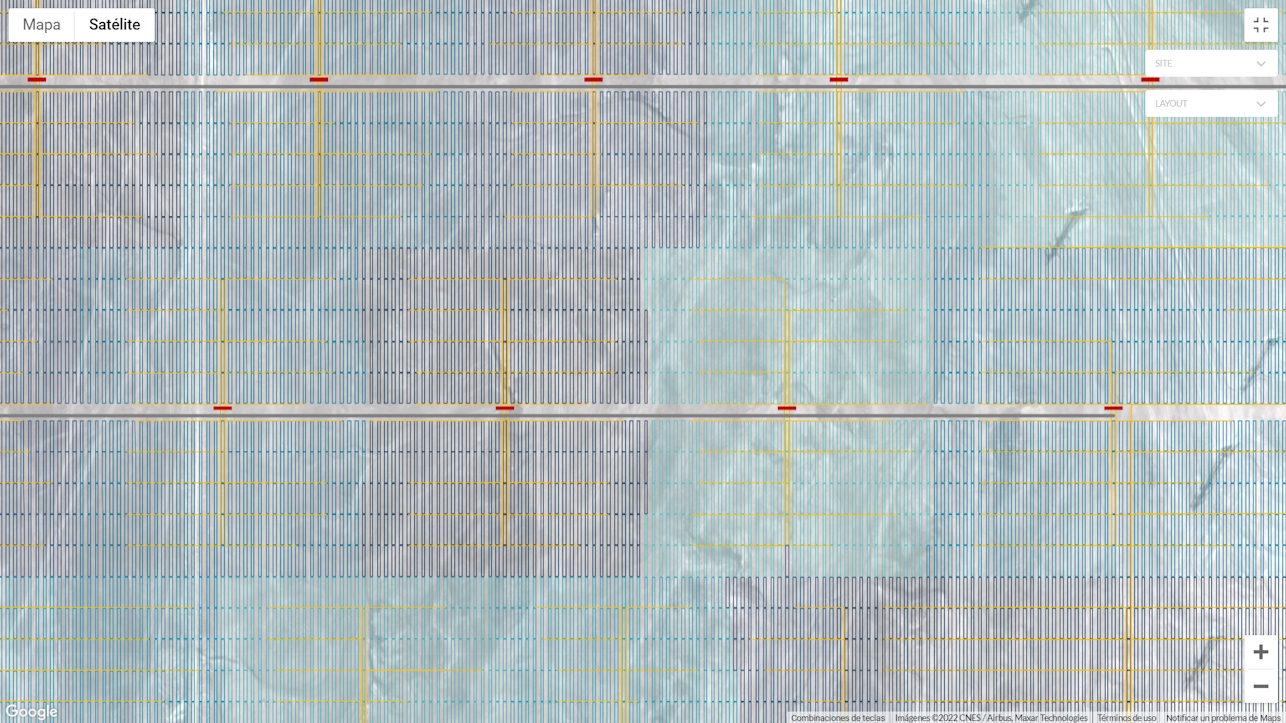

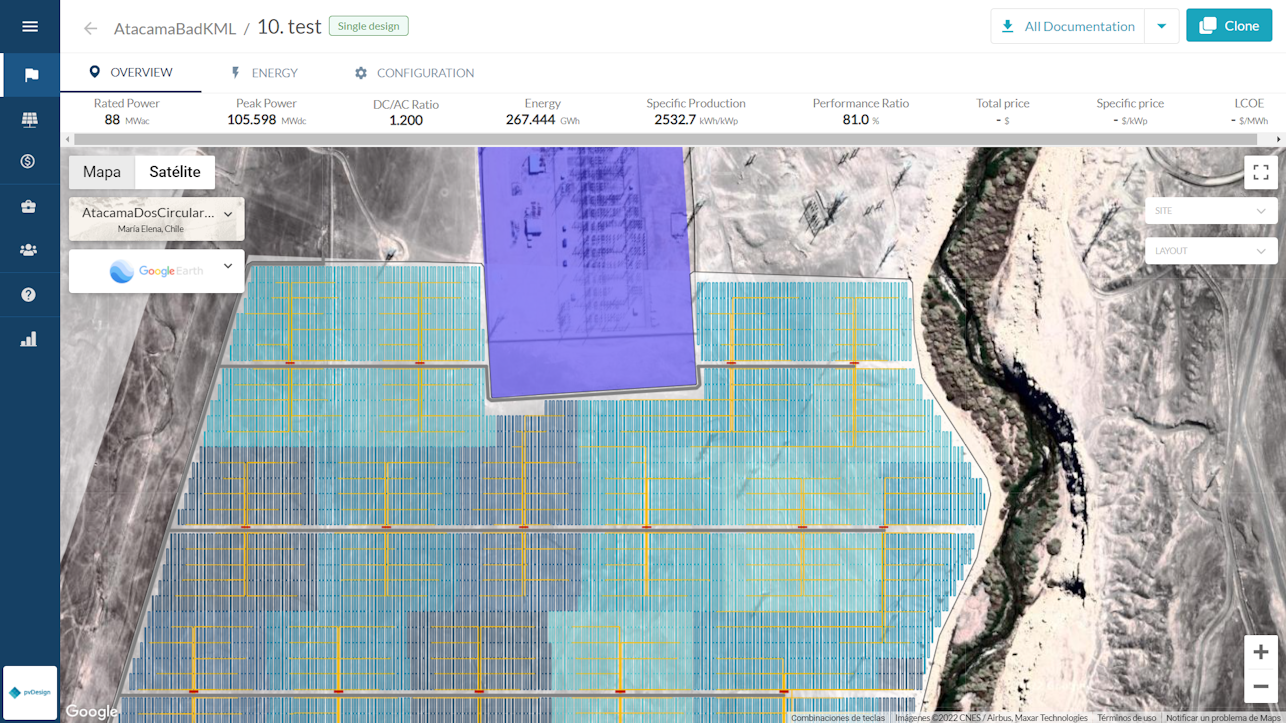

Source: RatedPower

Types of solar PV cabling

There are three types of solar PV cabling out there:

Medium-voltage (MV) cables: Medium-voltage (MV) cables interconnect power stations at the site and deliver power to the local substation. The correct configuration of these cables is essential, as they carry large volumes of energy from the solar plant to the grid. For that reason, it is important to design their routing to facilitate easy maintenance and reduce costly downtime.

Low-voltage (LV) cables: Low-voltage (LV) cables connect collector elements with the power station. They need to be installed in a way that they avoid passing below structures, as this would reduce their accessibility for maintenance.

String cables: These cables connect strings, or groups, of modules to the LV collector element. This requires straightforward routing, as the cables go in the air and are connected directly to the LV collector element.

Source: RatedPower

Grouping cable structures

What are the best ways to configure these cables for the most efficient power generation?

Medium Voltage

MV structures are grouped in squares to reduce their length, limiting energy losses and cable costs as they send electricity to the same medium voltage power stations. The power stations are also located as centrally as possible to reduce cable length.

Our goal building our platform is giving engineering and business teams at development companies a tool to speed up PV plant design and reduce LCOE. Now you can fully customize the MV routing between areas and the step-up substation —or between available areas—, reducing the time they spend on optimizing the layout for the construction team.

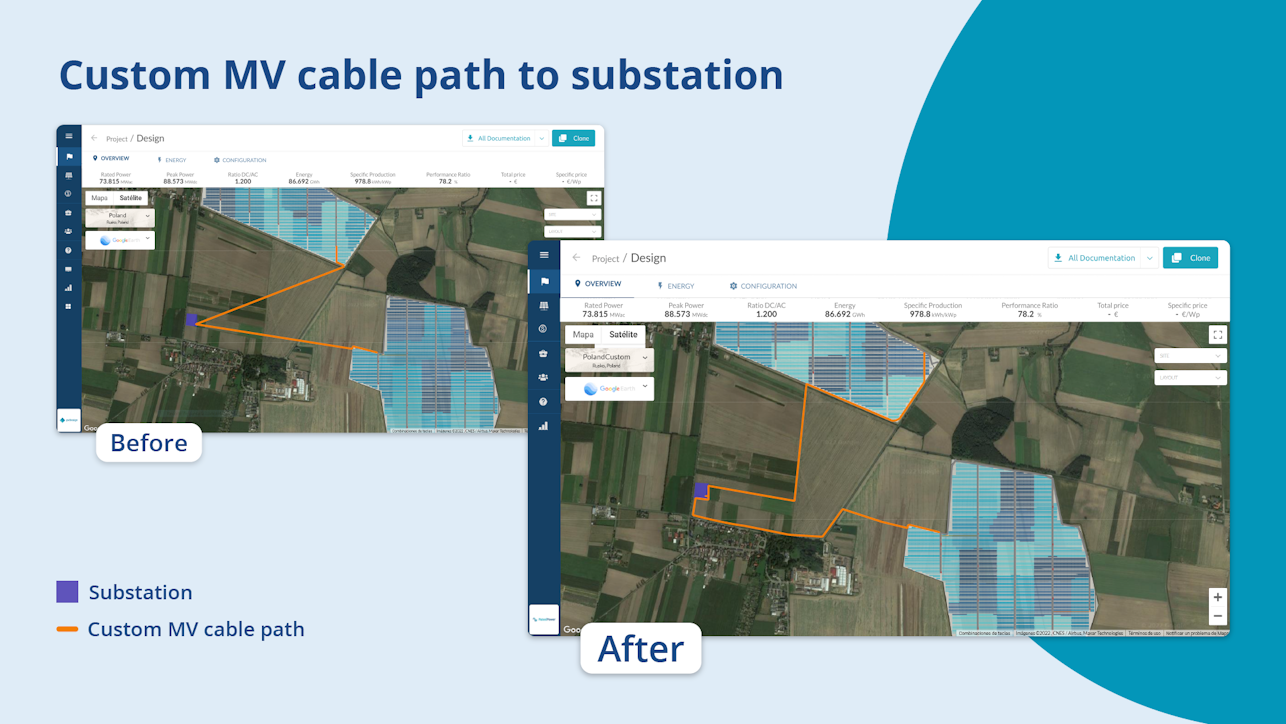

Custom MV cable path to substation

Once you define the path within the PV site definition file, the algorithms now take it them in account. The software transfer this cable settings at the layout design, the bill of quantities and the rest of technical documentation.

We thought this feature with the electrical engineers and solar PV developers in mind. It promotes the customization of their solution and shorten the polishing work in later stages, such as construction.

Low Voltage

LV structures send power to the same collector element, whether a string box, string inverter or other equipment. As with MV structures, they are typically grouped in squares. But there are other considerations that could require a slightly different configuration. For example, some systems – such as grounding conductors or direct current (DC) bus voltage conductors—will use rectangular groups so that structures from different rows are not connected together.

After creating the groups, the LV equipment is positioned to reduce the length of the cables that connect strings with these elements, find the best location for maintenance—such as near roads—and reduce the volume of trenches.

Modules

Solar modules are connected either in a series or in parallel. The number of panels connected together in an installation depends on several factors, such as the space available for the power plant, the size and type of solar panel used, and the type of inverter in the system—whether a string or central inverter.

Connecting solar panels in series increases the voltage of the solar array while maintaining the same amperage. Solar systems require a certain voltage for the inverter to work correctly, so this is key. Connecting solar panels in parallel increases the amperage but maintains the same voltage, enabling the use of more panels without exceeding the inverter’s voltage limits or its amperage limitations.

In a PV plant using a string inverter, a certain number of modules are connected to each other to create a single string that is then connected to the collector element. With a central inverter, the longer cables connect to the central unit, which converts more power.

String inverters are smaller than central inverters, so more are used in each energy system. As each row of panels connects to a single inverter, the cables can be shorter. Central inverters are often used in large utility-scale systems as fewer units are required, saving on equipment costs and enabling centralized control.

Whether a solar PV system uses a string or central inverter, the way the modules are grouped depends on several considerations, including reducing shading losses, limiting the length of cables and complying with the manufacturers’ specifications. Reducing shading is crucial, as the less the system is shaded the more electricity it can generate. And manufacturers often design systems so that the cable to connect one module to another requires modules to be grouped together in a specific way.

Curious on how RatedPower performs the electrical calculation through the PV plant? Take a look at our Electrical equipment and power cables methodology, a document that covers the criteria of each of the electrical cabling standards available in the software.

Choose RatedPower to design your solar energy system

The layout of cabling in a solar PV system can have a direct impact on the amount of electricity it sends to the grid and in turn the project’s return on investment.

If you are designing a solar plant project, RatedPower platform can help you automate the design to create the most efficient structure. Contact us today to find out more.

Latest stories

Related posts

Technology and engineering

Innovation in renewable energy: Developments expected in 2025

We look at the 10 biggest renewable industry developments that are making a green future possible, including perovskite solar cells, green hydrogen, and more.

Updated 18 MAR, 25

Market analysis

Breaking down solar farm costs: Free template inside

Updated 27 SEP, 21

Market analysis

Solar energy in Australia: a 2021 market analysis

Updated 11 MAY, 21

- RatedPower

- Solar energy blog

- Cabling solar installations for maximum efficiency